Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

As an experienced neodymium magnet manufacturer serving a wide range of industries worldwide, we've witnessed many orders successfully fulfilled, while others could have been avoided with proper planning. From our perspective, new buyers often make several mistakes when placing orders. By highlighting these mistakes, we hope to help customers save time, reduce costs, and obtain magnets that truly meet their needs.

Mistake 1: Not Specifying the Correct Coating

We often receive inquiries from buyers who simply request "neodymium magnets" without mentioning the surface treatment. The right coating—whether nickel, epoxy, zinc, or rubber—is critical to the magnet's performance in various environments. For example, magnets used in marine applications require higher corrosion resistance than those used in indoor applications. Neglecting this detail can significantly shorten the product's service life.

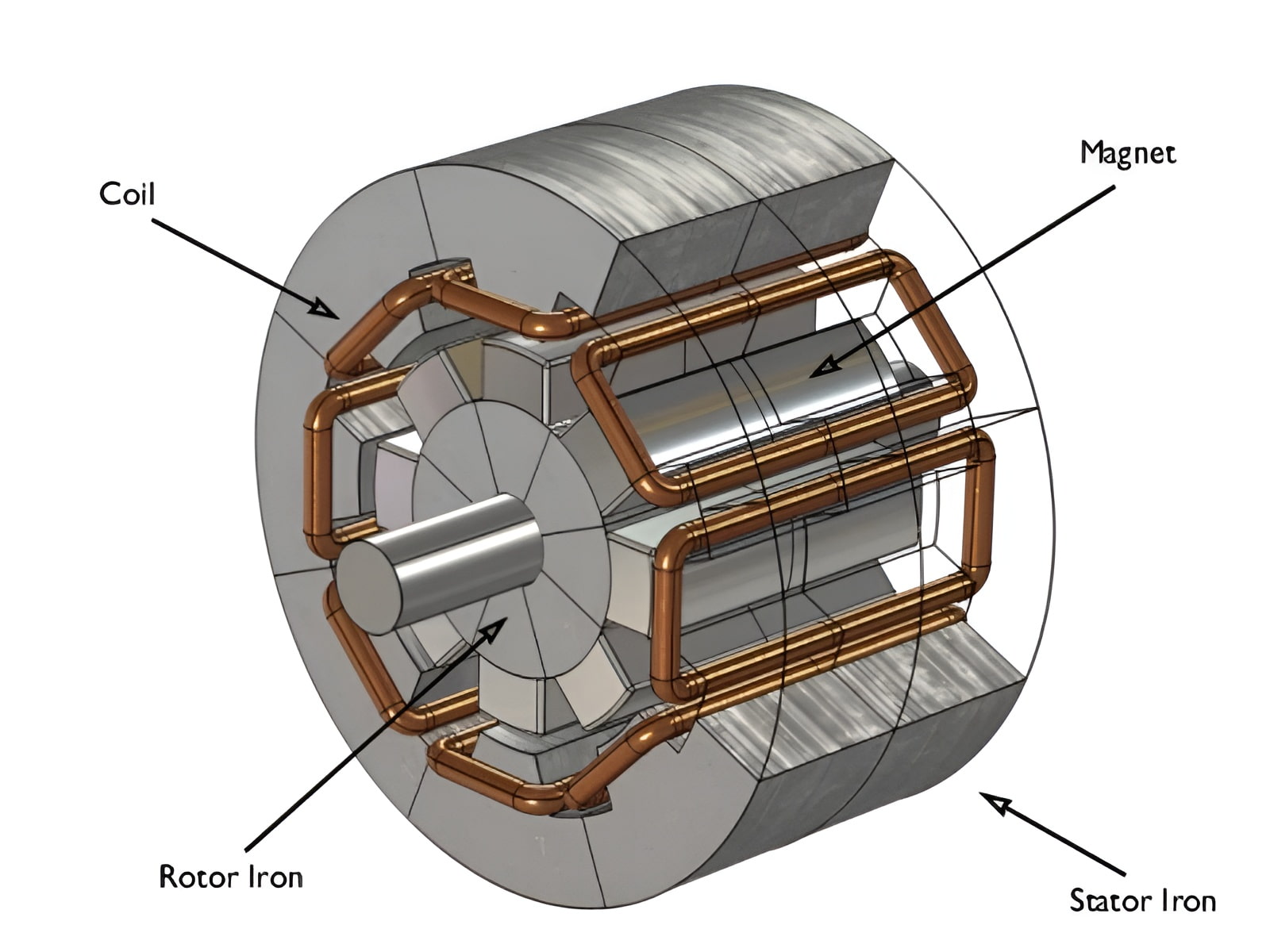

Mistake 2: Underestimating the Importance of Tensile Strength Calculations

Some customers order magnets based solely on size, assuming that larger sizes will yield higher tensile strength. In reality, the magnet's grade, shape, and mounting method all affect tensile strength. As a manufacturer, we often need to double-check with our customers to ensure the specifications they select are truly suitable for their intended application. Failure to clarify this upfront can result in magnets that are too weak or too strong, leading to excessive costs.

Mistake 3: Ignoring Tolerance Requirements

Precision is crucial. We sometimes receive orders with general dimensions but no tolerance specifications. In precision neodymium magnet applications, even slight deviations can cause assembly problems. We always recommend that buyers clearly specify tolerance requirements during the quote stage—this avoids delays, rework, or mismatches during the final installation.

Mistake 4: Prioritizing Price Over Quality Verification

We understand that cost is a key factor, but choosing the lowest-priced supplier without verifying quality can be risky. Some manufacturers may use recycled materials or not be RoHS and REACH compliant. As an established supplier, we always encourage buyers to request test reports and certifications. Focusing on quality from the outset can prevent larger issues later.

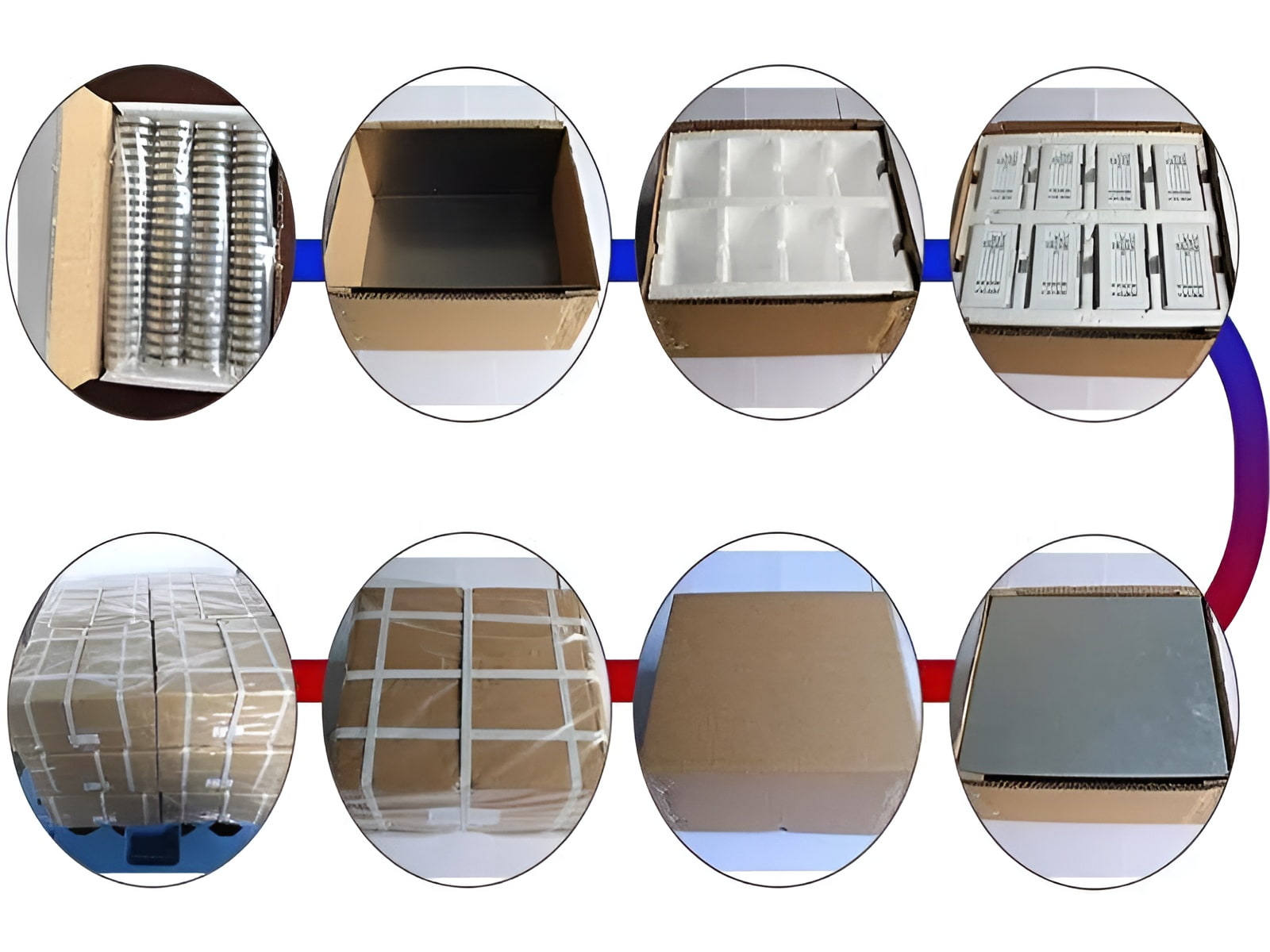

Mistake 5: Neglecting Packaging and Shipping Safety

Neodymium magnets are fragile and extremely strong. If improperly packaged, they can break or fracture during transport, posing a safety hazard. We have developed specialized packaging solutions to protect the product and ensure smooth customs clearance. Buyers who overlook this often face unnecessary damage or shipping delays.

If you're planning to buy neodymium magnets, our team can provide guidance on coating, tensile force calculations, tolerances, regulatory compliance, and secure packaging. Contact us today to discuss your project and let us help you avoid costly mistakes while ensuring the best possible outcome.

Hi! Click one of our members below to chat on