Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

In industrial applications, magnetic strength alone is insufficient to guarantee magnet performance and long-term reliability. The true determinant of magnet performance and long-term reliability is its long-term magnetic stability. Industrial neodymium magnets typically need to operate continuously under harsh conditions, such as high temperatures, mechanical vibration, external magnetic fields, and the effects of various environmental factors. Understanding how to achieve long-term stability is crucial for selecting the right magnet solution.

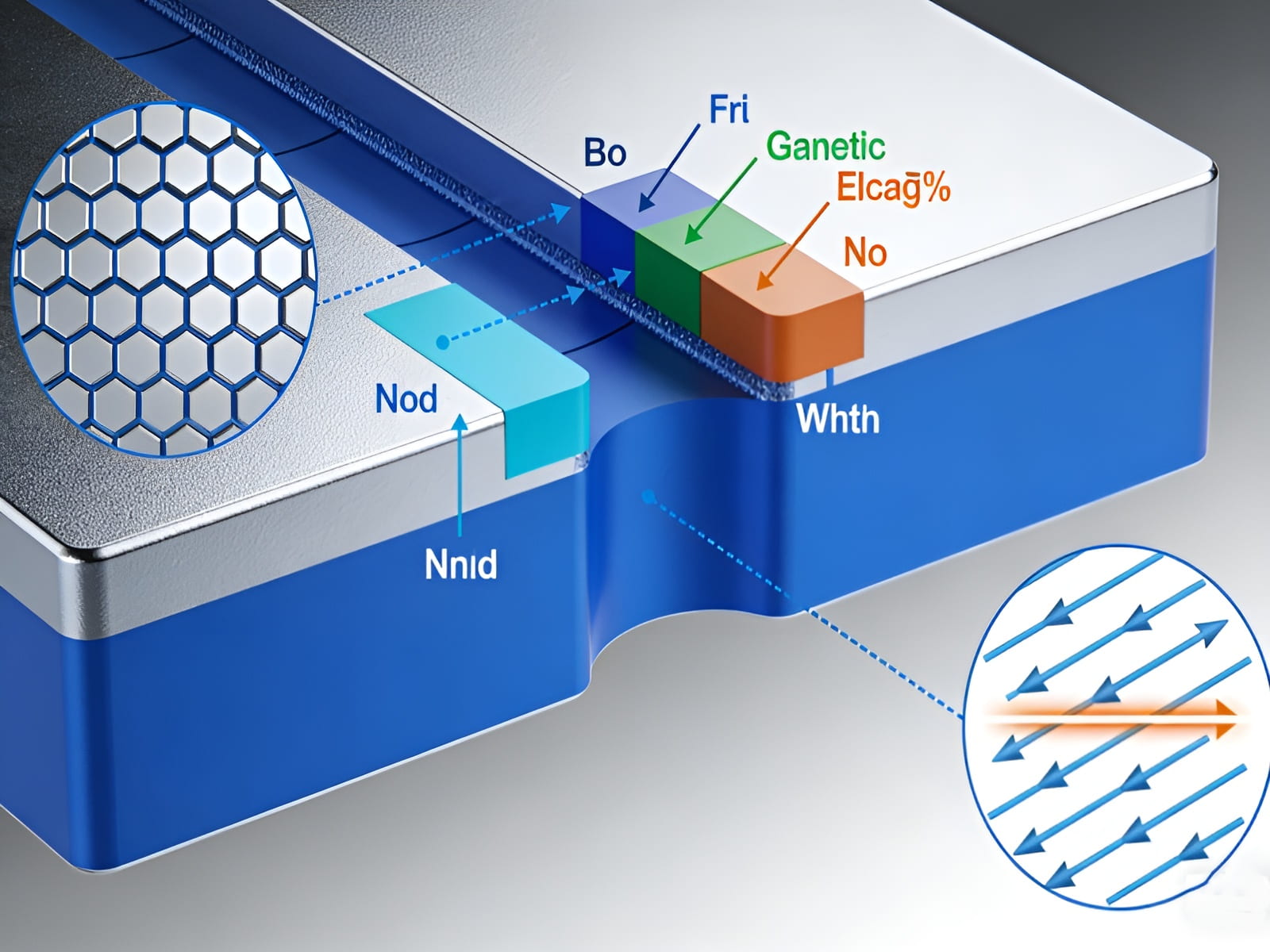

One of the most important factors affecting magnetic stability is material composition. Industrial-grade neodymium magnets employ controlled alloy formulations and precise grain structures to ensure stable magnetic orientation. Industrial environments often prefer neodymium magnets with higher coercivity because they better resist magnetic losses caused by high temperatures or external magnetic field disturbances.

Operating temperature is another critical consideration. Each neodymium magnet has a specified maximum operating temperature; exceeding this temperature leads to irreversible magnetic losses. In industrial applications such as motors, automation systems, and mechanical components, magnets are typically exposed to sustained high temperatures, rather than short-term temperature spikes. Selecting magnets specifically designed for high-temperature operation helps maintain stable magnetic performance over a longer service life.

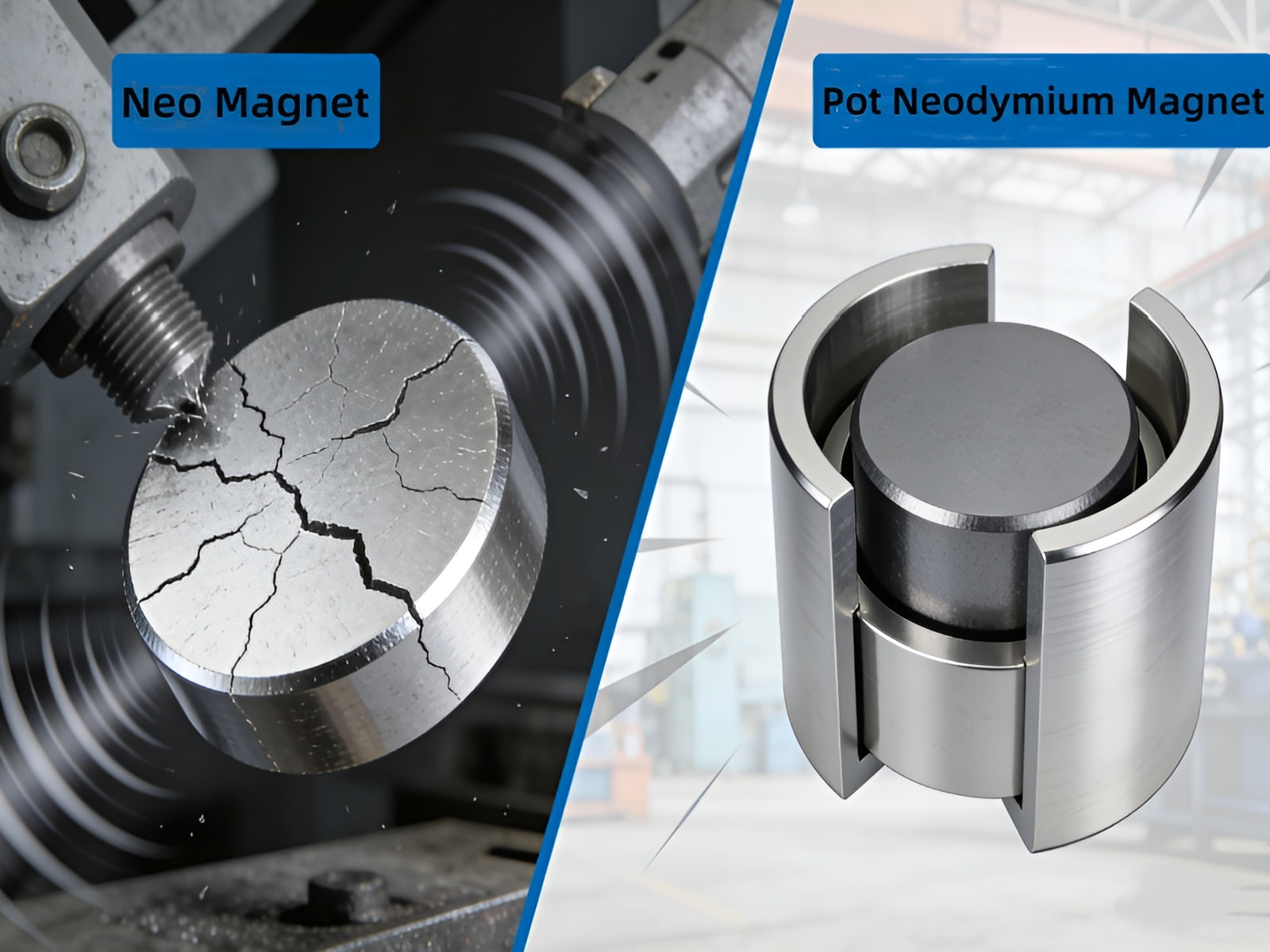

Mechanical stress also affects long-term stability. Industrial magnets may be subjected to vibration, shock, or repeated load cycles. While neodymium magnets are inherently brittle, uniform material density and proper mechanical support within the assembly can reduce internal stress and minimize the risk of performance degradation. The cup shaped pot magnet uses a steel outer shell structure, which can protect the magnet and improve magnetic circuit efficiency, thereby further enhancing stability.

Environmental exposure is equally important. Insufficient surface protection allows moisture, chemicals, and corrosive gases to compromise the integrity of the magnet. Industrial neodymium magnets typically employ advanced coatings, such as nickel coatings, epoxy coatings, or special multilayer coatings, to prevent corrosion, thus ensuring stable performance throughout their service life.

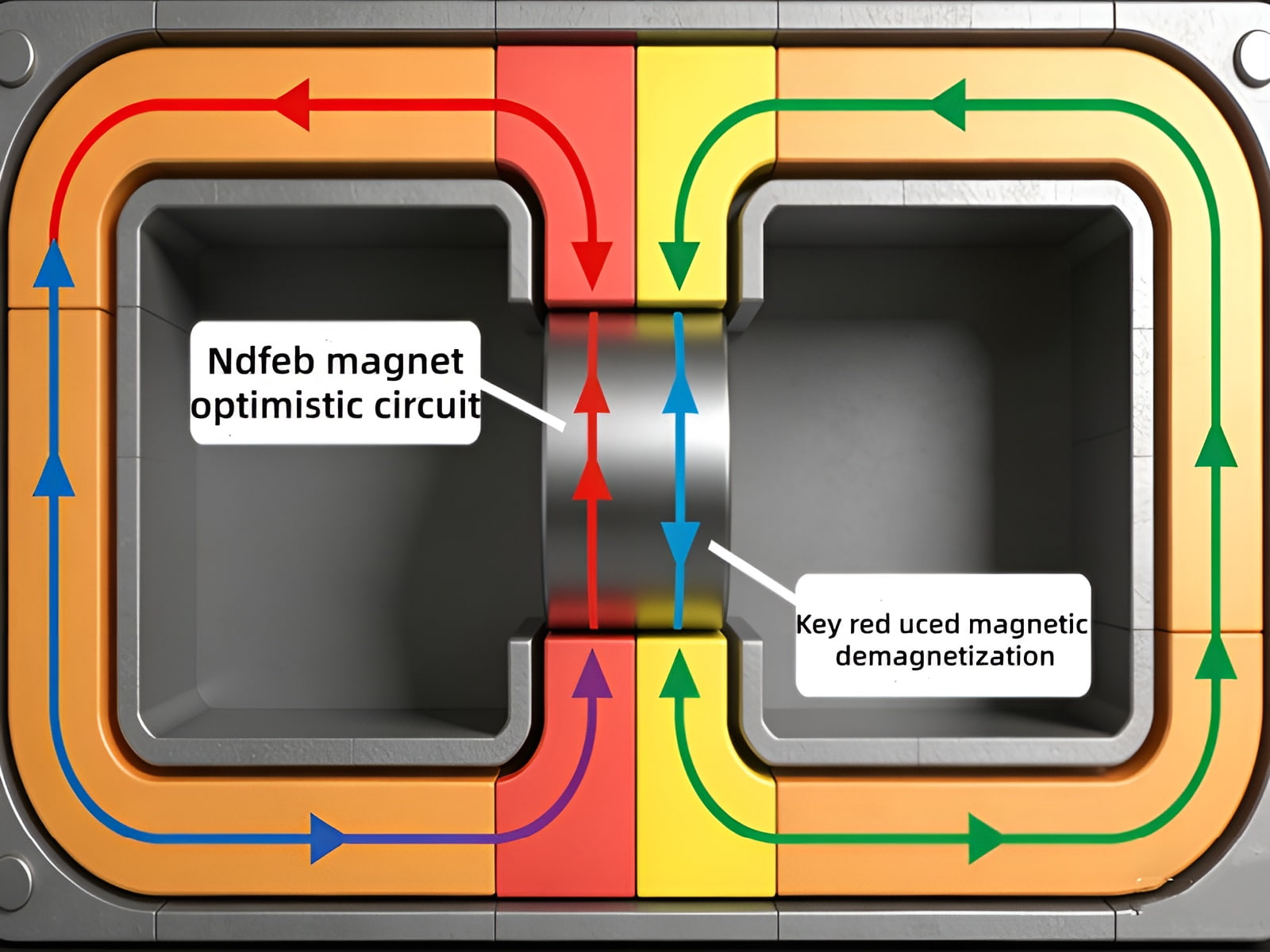

From a system design perspective, magnetic circuit optimization plays a crucial role in long-term stability. A well-designed magnetic circuit reduces demagnetizing forces and increases flux efficiency, allowing the magnet to operate within its performance limits, rather than under maximum stress.

In industrial environments, long-term magnetic stability depends on carefully selected materials, appropriate grades, protective design, and controlled operating conditions. If these factors are taken into account from the outset, strong neodymium magnets can maintain reliable and stable performance for many years, even in harsh industrial applications.

Hi! Click one of our members below to chat on