Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

Neodymium magnets come in a variety of shapes, with disc, ring, and block magnets being the most common. While they are all made of rare earth material and possess strong magnetism, their shape plays a crucial role in determining their performance in different applications. Choosing the right magnet shape can improve efficiency, safety, and overall product design.

Disc Magnets: Compact and Versatile

Disc magnets are one of the most widely used neodymium magnet shapes due to their simple and compact design. They are typically flat and round, making them ideal for applications where space is limited but strong magnetic force is required.

Common applications for disc magnets include electronics, sensors, packaging seals, and display systems. Their symmetrical shape allows for a uniform magnetic force distribution, which is beneficial for applications requiring precise alignment. Disc magnets are also frequently used in DIY projects and light industrial parts, where ease of installation is crucial.

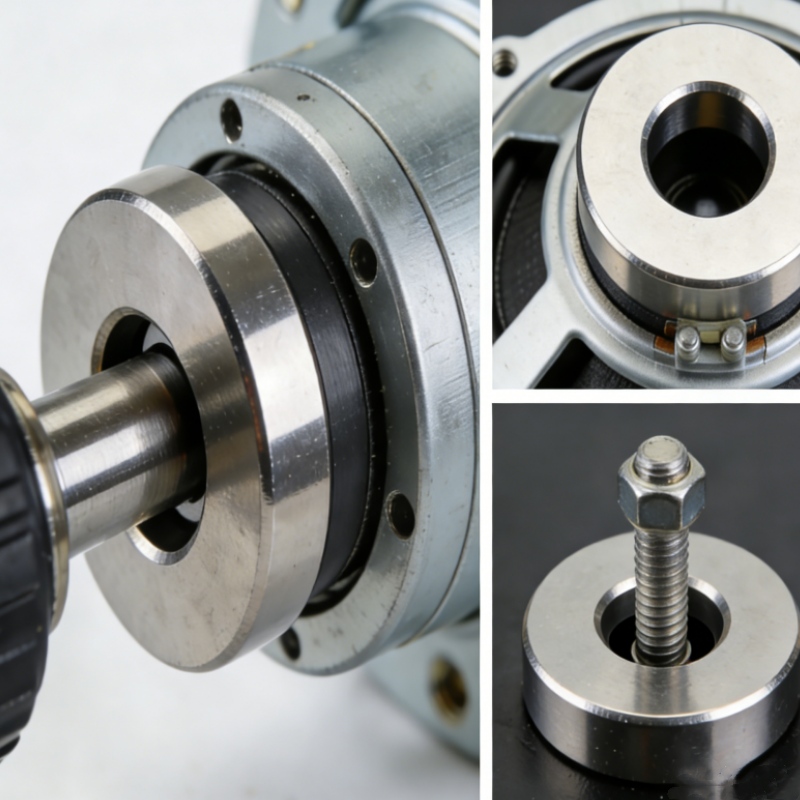

Ring Magnets: Designed for Shaft and Fastener Applications

Custom ring magnets have a hole in the center, making them suitable for applications involving shafts, bolts, or rotating parts. A central hole facilitates the secure mounting of magnets with screws or their integration around mechanical components.

These magnets are commonly used in motors, speakers, magnetic couplers, and fastening systems. Ring magnets are particularly suitable for applications requiring precise positioning or rotational movement. Compared to solid disc magnets, ring magnets are lighter while maintaining effective magnetic properties, making them a preferred choice in mechanical and electromechanical designs.

Block Magnets: Maximum Contact Area and Stability

Block magnets are a collective term for rectangular neodymium magnets and square neodymium magnets, designed to provide a larger contact area. This shape allows for greater magnetic force when used on flat steel surfaces and provides better stability in structural applications.

Block magnets are widely used in industrial automation, magnetic separators, tooling fixtures, and heavy-duty clamping systems. Their straight edges make them easier to align during assembly, ideal for applications requiring directional magnetic force. Furthermore, block magnets are often used in applications involving shear forces or requiring firm, non-rotational fixation.

Magnet Shape Selection Based on Application Scenarios

In practical applications, the magnet shape plays a crucial role in mounting methods, load orientation, and long-term performance. Designers and procurement personnel should assess factors such as available installation space, contact area, vibration, and displacement during the early design phase. Choosing the right magnet shape can improve stability, simplify installation, and reduce material usage. By matching the magnet shape to actual operating conditions and product structure, reliable performance can be achieved in a variety of applications while maintaining cost-effectiveness and design flexibility.

Hi! Click one of our members below to chat on