Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

When customers pick up a finished neodymium magnet, their first impression is often its smooth, shiny, uniform, and near-perfect surface. However, beneath this silky surface lies a series of highly controlled engineering processes. Whether it's nickel plating, zinc plating, epoxy resin, gold plating, or poly(p-xylene) coating, each layer requires precision manufacturing to ensure its performance, durability, and corrosion resistance.

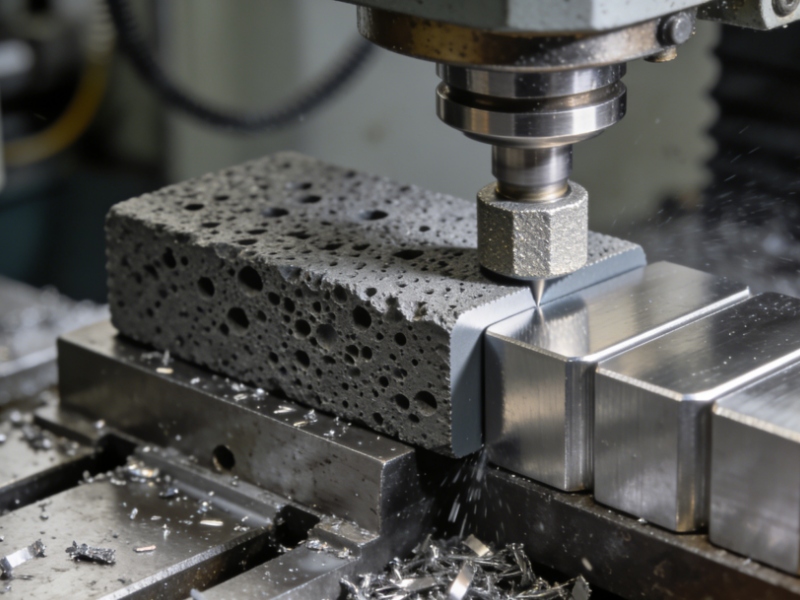

The formation of the smooth surface begins with the original sintered neodymium magnet, whose surface is typically porous and rough. Before applying any coating, each magnet must be carefully ground and polished using diamond tools to achieve tight dimensional tolerances. This step determines not only the final precision of the magnet but also the uniformity of the coating adhesion.

Next comes surface activation—a step invisible to the naked eye but crucial for coating adhesion. The magnet undergoes ultrasonic cleaning, degreasing, and chemical treatment to remove minute impurities. This ensures that each coating layer adheres firmly and does not peel or blister over time.

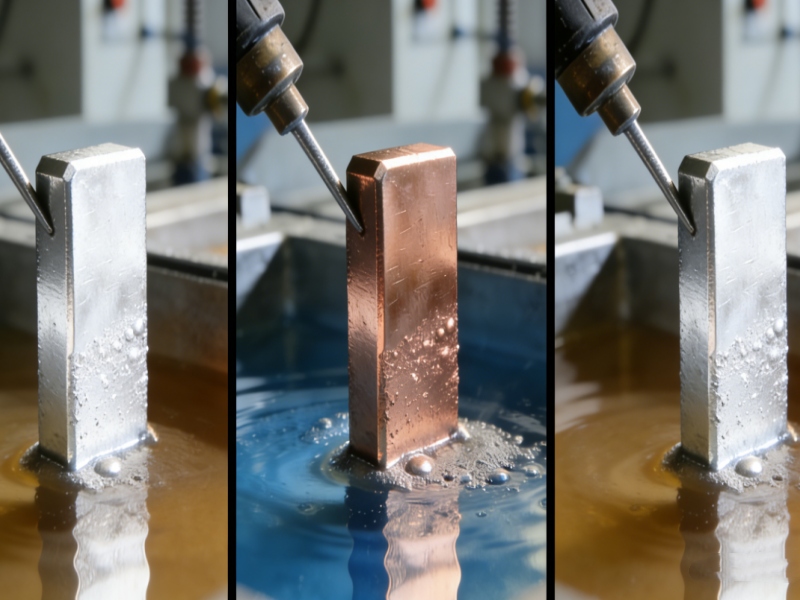

Different coatings require different engineering techniques. For example, the classic ndfeb magnets nickel-copper-nickel electroplating process requires multiple plating cycles. Each layer serves a specific purpose: enhancing corrosion resistance, improving mechanical stability, and achieving a bright metallic luster. While zinc plating is thinner, it requires precise current control to achieve a uniform matte surface, making it suitable for cost-sensitive applications.

Epoxy coatings go a step further. They employ controlled spraying or dip-coating processes followed by high-temperature curing to form a smooth, wear-resistant outer shell. The challenge lies in maintaining consistent coating thickness (typically within the 0.02-0.05 mm range) while avoiding bubbles or drips.

For high-end applications, specialized coatings such as gold and poly(p-xylene) introduce greater engineering complexity. Gold plating requires stringent environmental controls to prevent contamination, while poly(p-xylene) coatings, using vapor deposition, create an extremely smooth, pinhole-free protective film, ideal for medical and sensor components.

After coating, each magnet undergoes visual inspection, thickness testing, and adhesion testing, such as cross-cut adhesion testing or salt spray corrosion testing. Only magnets that meet all standards can achieve the final polished finish expected by the customer.

Behind every smooth coting neo magnet lies not just a coating, but a complete engineering system that ensures its stability, reliability, and long-term performance in practical applications.

Hi! Click one of our members below to chat on