Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

When evaluating neodymium magnets, most buyers focus on magnet grade, tensile strength, or coating, often overlooking magnet density. In reality, magnet density plays a crucial role in determining magnetic properties, mechanical strength, and long-term stability. Understanding how magnet density affects performance helps engineers and buyers make more informed material and design decisions.

What is Magnet Density?

Magnetic density refers to the mass per unit volume of a magnet, typically expressed in g/cm³. For sintered neodymium iron boron magnets, density is closely related to the compactness of the internal grain structure after sintering. Higher density generally means less internal porosity and a more uniform microstructure.

Density and Magnetic Properties

In neodymium magnets, magnetic properties depend on the arrangement and interaction of magnetic domains within the material. Higher density allows these domains to align more closely, improving magnetic flux continuity. Therefore, magnets with higher density generally exhibit better magnetic properties, such as higher remanence (Br) and more stable performance.

Low-density magnets may contain tiny voids formed during pressing or sintering. These voids can block magnetic flux paths, slightly reducing effective magnetic strength and consistency, especially in precision applications.

Density and Mechanical Properties

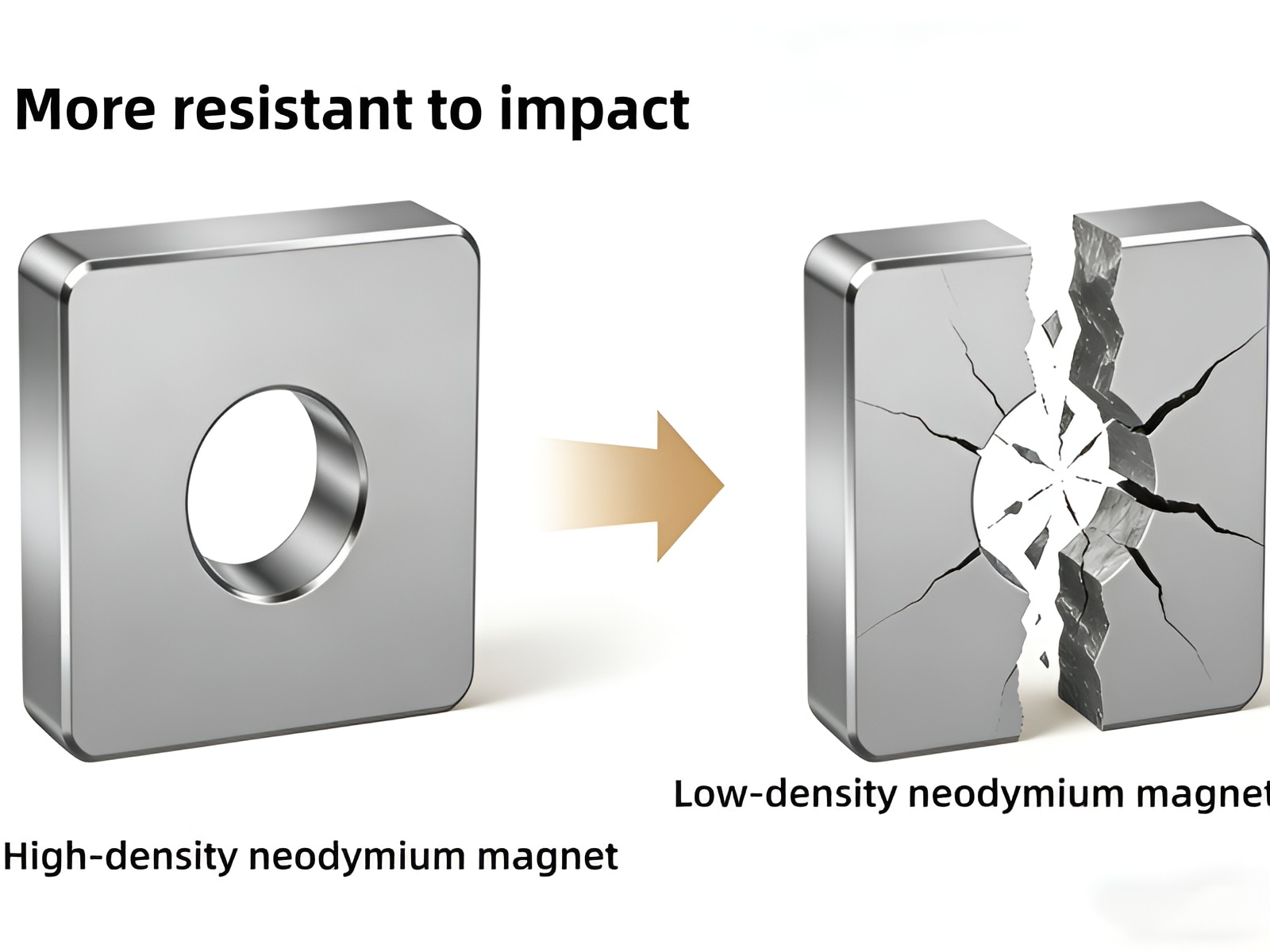

Density also affects the mechanical properties of neodymium magnets. Higher-density magnets tend to have better structural integrity and are more resistant to impacts or cracking during handling and assembly. While high quality neodymium magnets are inherently brittle, uniform density reduces weak points within the material, thus improving overall reliability.

Impact on Application Performance

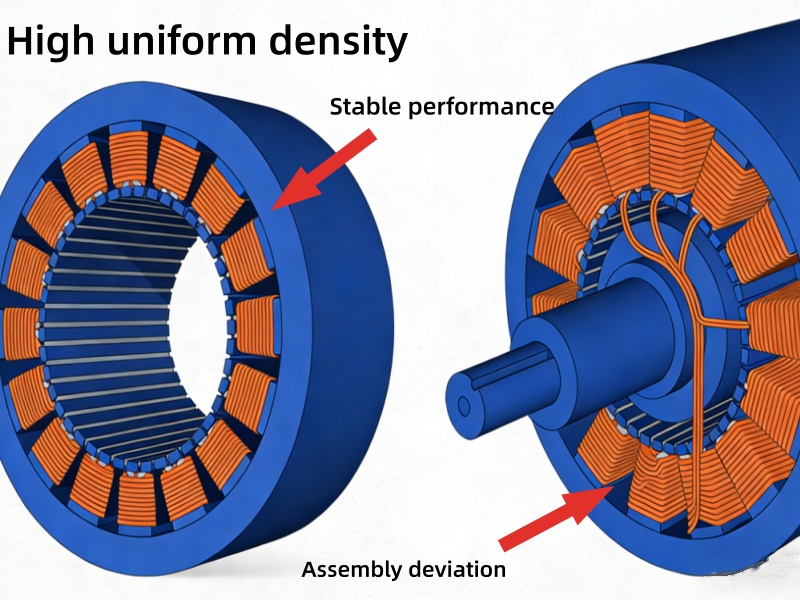

In practical applications, density affects the reliability of magnets under load, vibration, or repeated use. For example, in motors, sensors, or magnetic components, uniform density helps achieve predictable magnetic properties and tighter performance tolerances. Conversely, inconsistent density can lead to batch-to-batch variations, affecting assembly accuracy and product consistency.

Magnet density is also closely related to processing quality. Higher-density magnets typically allow for cleaner cuts and grinding, thus contributing to tighter dimensional tolerances during production.

Conclusion

While magnet density is not always listed separately, it is a fundamental indicator of neodymium magnet material quality. Higher density results in stronger magnetic properties, better structural stability, and more consistent performance in practical applications. When seeking durable strong neodymium magnets, buyers should consider magnet density in addition to magnet grade, coating, and operating conditions.

Hi! Click one of our members below to chat on