Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

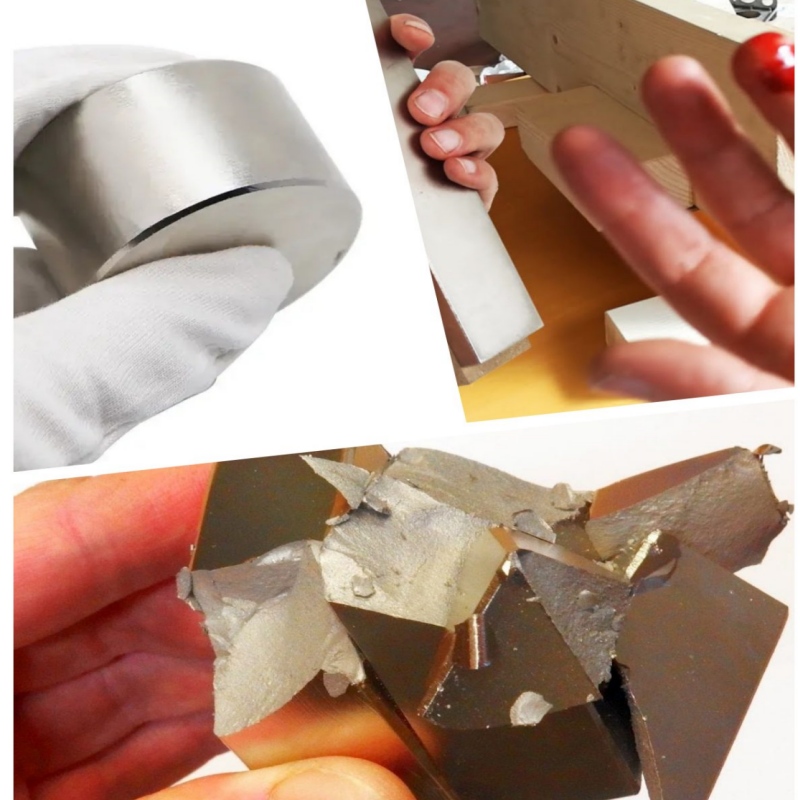

Neodymium magnets are widely used in applications ranging from motors and sensors to packaging and medical devices. However, their exceptional strength also presents safety challenges. One of the most common hazards is pinching, where a finger or skin becomes trapped between two magnets or between a magnet and a steel surface. Such accidents can result in bruises, cuts, and even fractures.

To minimize these risks, manufacturers and engineers must consider safety during the design phase, ensuring that products and assembly processes effectively protect workers.

Why do pinching injuries occur with neodymium magnets?

Design Strategies to Enhance Safety

1. Optimize Magnet Size and Shape

Using multiple smaller neodymium magnets, rather than a single large magnet, can help reduce the risk of injury. Adding rounded edges or chamfers can also minimize sharp impact points.

2. Integrate Non-Magnetic Spacers

Plastic, aluminum, or brass spacers can act as barriers to prevent direct impact between neodymium magnets.

3. Apply Protective Coatings or Enclosures

Epoxy, rubber, or plastic coatings can help cushion impacts. In critical applications, neodymium magnets can be enclosed in ABS or steel enclosures.

4. Control Assembly Distances

Use jigs, fixtures, or robotic tools to keep workers away from the magnets during installation. This can reduce the risk of pinching accidents.

5. Consider Shielding or Partial Magnetization

Large neodymium magnets can be shipped magnetically shielded or partially magnetized and then fully magnetized after installation.

Workplace Best Practices

Neodymium magnets offer unparalleled strength and efficiency, but this powerful performance also requires rigorous safety considerations. Manufacturers can prevent pinch injuries through safety design measures such as optimized sizing, gasketing, coatings, controlled assembly, and shielding. Combined with training and protective equipment, these strategies can protect workers and support smooth, reliable production.

Hi! Click one of our members below to chat on