Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

Every powerful magnet begins with an idea—a need for precision, strength, and innovation. But how do you transform a small concept into a fully functional neodymium magnet suitable for global applications? The entire process from prototyping to mass production is a meticulously planned process that blends engineering expertise, materials science, and rigorous quality control.

The process begins with customer consultation and design. Every project is unique, whether it's a sensor, motor, magnetic component, renewable energy system, or consumer electronics. Our engineers work closely with customers to understand their specific requirements, including size, shape, tolerances, magnetic grade, and operating environment. Advanced tools like CAD drawings and magnetic simulation help predict performance, ensuring the final magnet meets both functional and environmental requirements.

Once the design is complete, the project enters the prototyping phase. During this phase, we produce small batches neo magnets to verify key parameters such as pull-out strength, dimensional accuracy, and surface coating performance. Sometimes, multiple iterations are required to compare the performance of different grades or coatings (such as nickel, epoxy, or zinc) under varying temperatures, humidity, or mechanical stress. We provide detailed test reports and even video demonstrations so customers can fully understand the magnet's performance under real-world conditions.

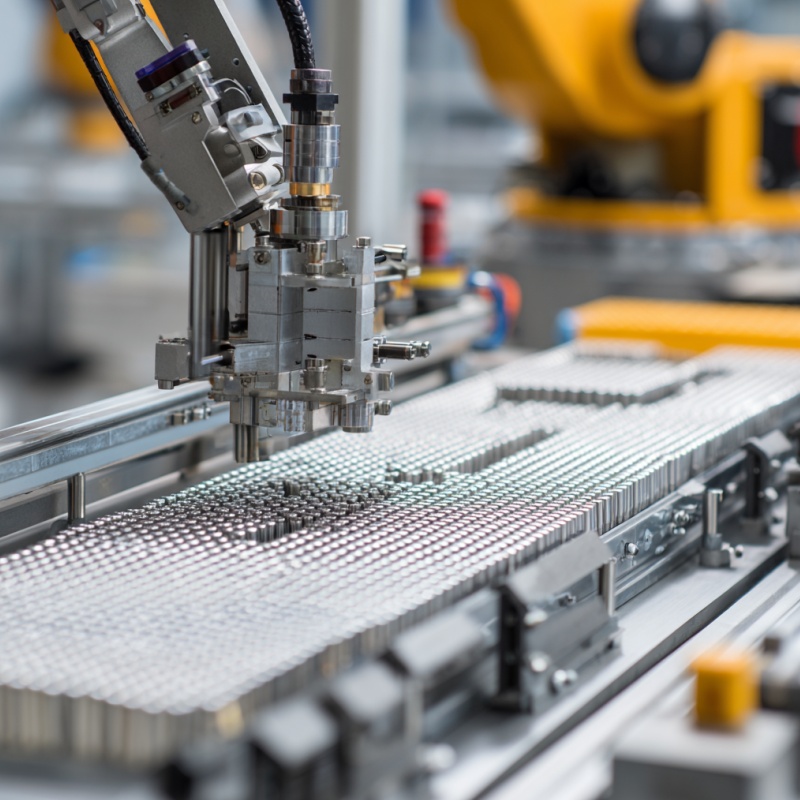

Once the prototype is approved, mass production can begin. The raw materials—neodymium, iron, and boron—are processed with extreme precision. The magnets are sintered, cut, and formed according to approved specifications. They are then electroplated or coated to protect against corrosion, wear, and environmental factors. Throughout the production process, each batch of magnets undergoes rigorous quality inspections, including magnetic pull tests, visual inspections, and corrosion tests, to ensure consistent performance across thousands of units.

The final step is assembly, packaging, and shipping. Proper magnetic shielding and meticulous packaging are crucial to prevent damage during transportation. We handle logistics according to global standards, ensuring timely delivery by air, sea, or rail, while complying with all export regulations.

From concept to delivery, this journey highlights not only the complexity of neodymium magnet manufacturing but also the importance of customization, quality, and reliability. For our company, we not only manufacture magnets; we transform innovative ideas into practical solutions that power industries around the world. We combine advanced technology, rigorous testing, and customer collaboration to help our customers create magnetic solutions that drive performance, efficiency, and innovation.

Hi! Click one of our members below to chat on