Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

When people see a neodymium magnet, they imagine a solid, unchanging piece of metal. But in the world of rare earth magnetic materials, the truth is far more delicate. Even a tiny change in raw materials, additives, or ratios can dramatically alter a magnet’s behavior. These differences may be invisible to the naked eye but crucial for stability, strength, and durability.

Neodymium magnets are primarily composed of Nd, Fe, and B, but their real performance comes from the exact proportions of these elements. For example, a small increase in neodymium content boosts magnetic strength, while slightly more iron improves durability but reduces coercivity. Manufacturers must balance each element to create the desired magnetic grade—from N35 to N52.

A simple 0.5% shift in the formula may sound minimal, but for high performance ndfeb magnets, it can mean:

better alignment of magnetic domains

higher maximum energy product

or reduced long-term stability if the ratio is off

This is why different batches of magnets from different factories can vary even if they appear identical.

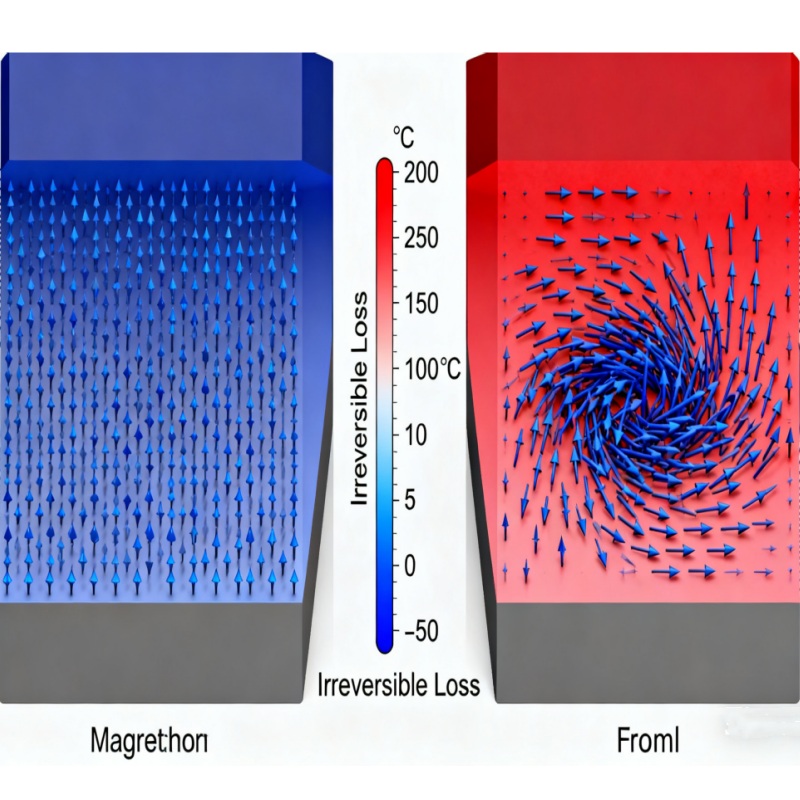

Additives such as dysprosium (Dy) or terbium (Tb) play a crucial role in improving high-temperature performance.

Dy increases coercivity, allowing the magnet to maintain strength at elevated temperatures. But it is extremely expensive, so manufacturers use it carefully — sometimes adding just 1% can push a magnet from “general use” to “motor-grade.”

Without enough Dy, magnets may:

demagnetize when heated

lose strength over time

fail in demanding environments like automotive motors or sensors

With too much Dy, cost increases sharply without noticeable benefit. Finding the balance is an engineering art.

The purity of raw materials also matters. Impurities such as oxygen or carbon can disrupt grain structure and weaken performance. High-purity materials allow the magnet to form more stable crystalline phases, which leads to:

stronger magnetic flux

better consistency

improved lifespan

Strong Neo magnet made with lower-purity powder may chip more easily, corrode faster, or show inconsistent pull force.

Even when the formula is the same, differences in powder size, grain uniformity, and sintering temperature can change how the grains lock together. A slight variation in sintering—sometimes just 1–2°C—can produce magnets with noticeably different strength or coercivity.

So, can small changes really affect magnet performance? Absolutely. A minor adjustment in material ratio, additive content, or purity can lead to major differences in strength, durability, and stability. Behind every strong powerful neodymium magnet is a precise combination of raw materials and micro-level engineering—proof that even the smallest details can shape powerful results.

Hi! Click one of our members below to chat on