Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

The round magnets with hole feature a solid, sturdy, shiny nickel plated, ensures smooth non-scratching surface that is corrosion resistant, premium quality and longevity, can perfectly meet your needs.

Size :

CustomizedColor :

SilverOrder(MOQ) :

100pcsGrade :

N35-N52Sample :

AvailableLead Time :

3-15daysPayment :

Paypal/TT/Credit CardRare Earth Round Neodymium Magnets With Countersunk Holes

Product Description

Density: 7.5g/cm3

Tolerances: ±0.004" x ±0.004"

Material: Neodymium

Plating/Coating: Ni-Cu-Ni (Nickel)

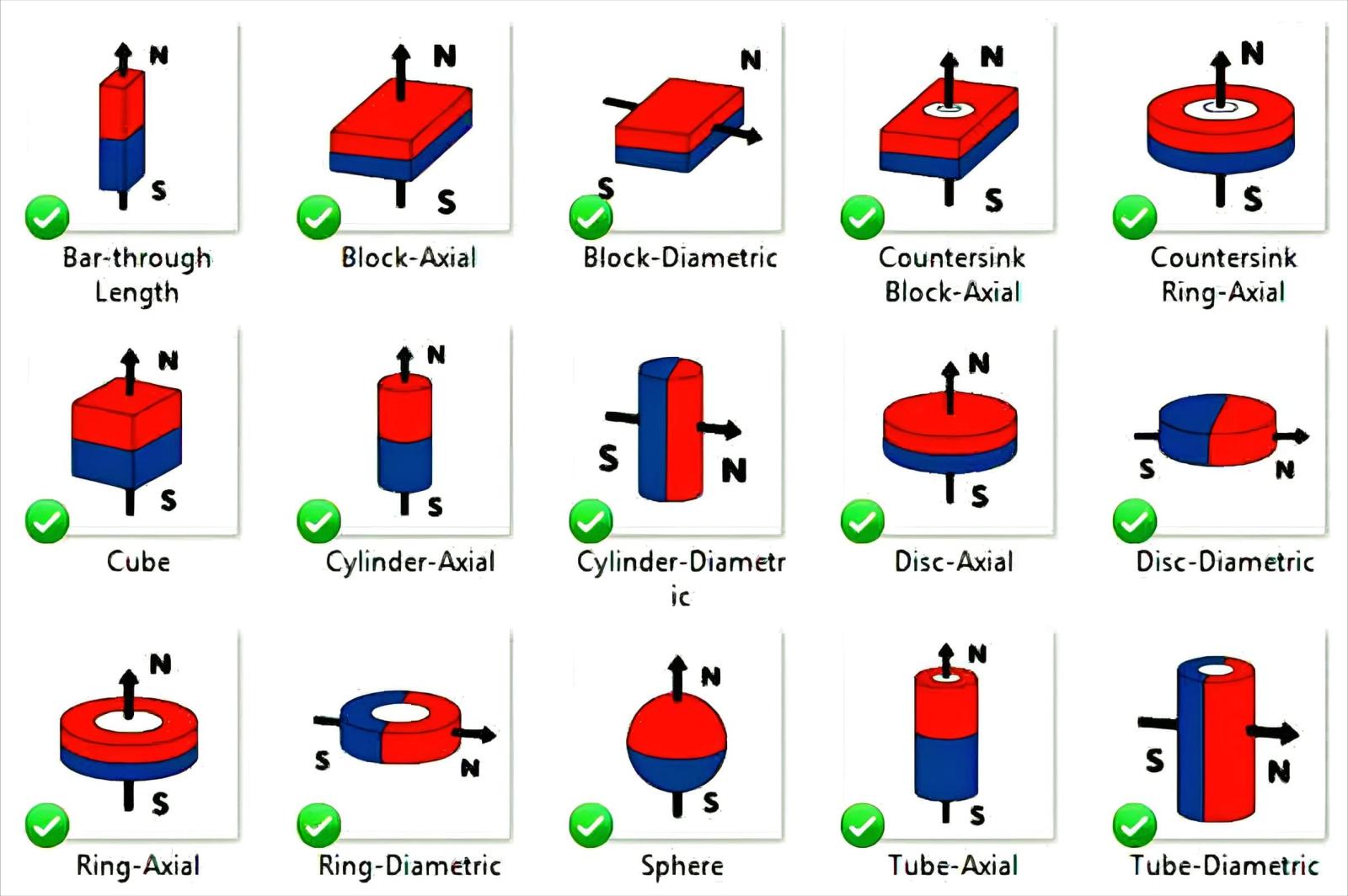

Magnetization Direction: Axial (Poles on Flat Ends)

Max Operating Temp: 176ºF (80ºC)

Features

1. High Magnetic Strength: Round neodymium countersunk magnets are known for their incredibly strong magnetic force, making them ideal for applications that require a powerful hold in a compact size.

2. Countersunk Hole: The countersunk hole allows for easy mounting with screws, providing a secure, flush fit that is perfect for various installations.

3. Material: Made from an alloy of neodymium, iron, and boron (NdFeB), these magnets are incredibly durable and powerful, making them one of the strongest types of permanent magnets available.

4. Durability and Corrosion Resistance: These rare earth magnets with countersunk holes are often coated with materials like nickel, epoxy, or zinc, offering excellent corrosion resistance and longevity, even in harsh environments.

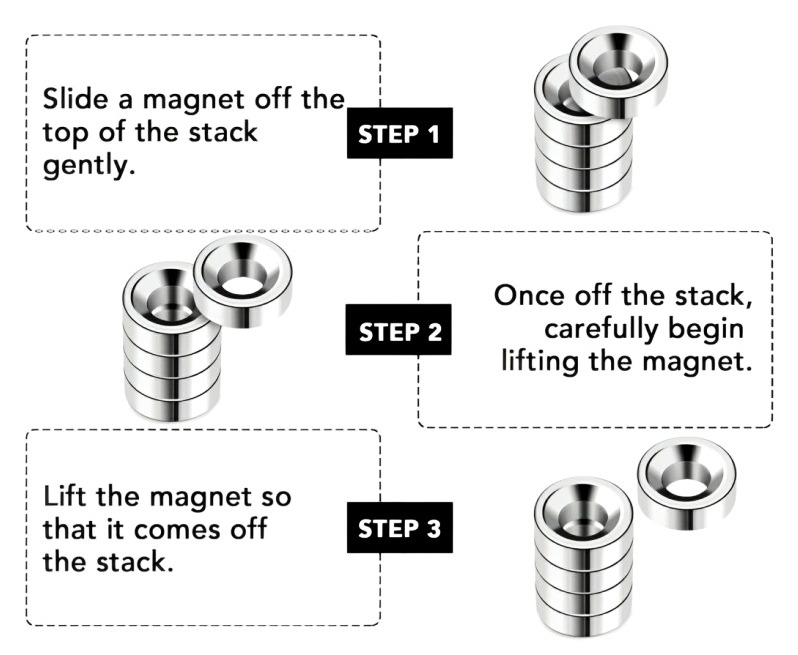

How to Separate Magnets

Customization

| Neodymium | Br | Hcb | Hcj | (Bh)max | Tw | ||||

| Grade | mT | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | ℃ |

| N35 | 1170-1220 | 11.7-12.2 | >868 | >10.9 | >955 | >12 | 263-287 | 33-36 | <80 |

| N38 | 1220-1250 | 12.2-12.5 | >899 | >11.3 | >955 | >12 | 287-310 | 38-39 | <80 |

| N40 | 1250-1280 | 12.5-12.8 | >907 | >11.4 | >955 | >12 | 302-326 | 38-41 | <80 |

| N42 | 1280-1320 | 12.8-13.2 | >915 | >11.5 | >955 | >12 | 318-342 | 40-43 | <80 |

| N45 | 1330-1370 | 13.3-13.7 | >915 | >11.5 | >955 | >12 | 342-367 | 41-44 | <80 |

| N48 | 1380-1420 | 13.8-14.2 | >923 | >11.6 | >955 | >12 | 366-390 | 46-49 | <80 |

| N50 | 1400-1450 | 14.0-14.5 | >796 | >10 | >876 | >11 | 382-406 | 48-49 | <80 |

| N52 | 1430-1480 | 14.3-14.8 | >796 | >10 | >876 | >11 | 398-422 | 50-53 | <80 |

| 35M | 1170-1220 | 11.7-12.2 | >868 | >10.9 | >1114 | >14 | 263-297 | 33-36 | <100 |

| 38M | 1220-1250 | 12.2-12.5 | >899 | >11.3 | >1114 | >14 | 297-310 | 36-39 | <100 |

| 40M | 1250-1280 | 12.5-12.8 | >923 | >11.6 | >1114 | >14 | 302-326 | 38-41 | <100 |

| 42M | 1280-1320 | 12.8-13.2 | >955 | >12 | >1114 | >14 | 318-342 | 40-43 | <100 |

| 48M | 1360-1430 | 13.6-14.3 | >1027 | >12.9 | >1114 | >14 | 366-390 | 46-49 | <100 |

| 50M | 1400-1450 | 14.0-14.5 | >1033 | >13 | >1114 | >14 | 382-406 | 48-51 | <100 |

| 33H | 1130-1170 | 11.3-11.7 | >836 | >10.5 | >1353 | >17 | 247-271 | 31-34 | <120 |

| 35H | 1170-1220 | 11.7-12.2 | >868 | >10.9 | >1353 | >17 | 263-287 | 33-36 | <120 |

| 38H | 1220-1250 | 12.2-12.5 | >899 | >11.3 | >1353 | >17 | 287-310 | 36-39 | <120 |

| 40H | 1250-1280 | 12.5-12.8 | >923 | >11.6 | >1353 | >17 | 302-326 | 38-41 | <120 |

| 42H | 1280-1320 | 12.8-13.2 | >955 | >12 | >1353 | >17 | 318-342 | 40-43 | <120 |

| 45H | 1300-1360 | 13-13.6 | >963 | >12.1 | >1353 | >17 | 326-358 | 43-46 | <120 |

| 48H | 1370-1430 | 13.7-14.3 | >995 | >12 | >1353 | >17 | 366-390 | 46-49 | <120 |

| 30SH | 1080-1130 | 10.8-11.3 | >804 | >10.1 | >1592 | >20 | 223-247 | 28-31 | <150 |

| 33SH | 1130-1170 | 10.3-11.7 | >844 | >10.6 | >1592 | >20 | 247-271 | 31-34 | <150 |

| 35SH | 1170-1220 | 11.7-12.2 | >876 | >11 | >1592 | >20 | 263-287 | 33-36 | <150 |

| 38SH | 1220-1250 | 12.2-12.5 | >907 | >11.4 | >1592 | >20 | 287-310 | 36-39 | <150 |

| 40SH | 1240-1280 | 12.5-12.8 | >939 | >11.8 | >1592 | >20 | 302-326 | 36-41 | <150 |

| 42SH | 1280-1320 | 12.8-13.2 | >987 | >12.4 | >1592 | >20 | 318-342 | 40-43 | <150 |

| 45SH | 1320-1380 | 13.2-13.8 | >1003 | >12.6 | >1592 | >20 | 342-366 | 43-46 | <150 |

| 28UH | 1020-1080 | 10.2-10.8 | >764 | >9.6 | >1990 | >25 | 207-231 | 26-29 | <180 |

| 30UH | 1080-1130 | 10.8-11.3 | >812 | >10.2 | >1990 | >25 | 223-247 | 28-31 | <180 |

| 33UH | 1130-1170 | 11.3-11.7 | >852 | >10.7 | >1990 | >25 | 247-271 | 31-36 | <180 |

| 35UH | 1170-1220 | 11.8-12.2 | >860 | >10.8 | >1990 | >25 | 263-287 | 33-36 | <180 |

| 38UH | 1220-1250 | 12.2-12.5 | >876 | >11 | >1990 | >25 | 287-310 | 36-39 | <180 |

| 40UH | 1250-1280 | 12.5-12.8 | >899 | >11.3 | >1990 | >25 | 302-326 | 31-41 | <180 |

| 28EH | 1040-1090 | 10.4-10.9 | >780 | >9.8 | >2388 | >30 | 207-231 | 26-29 | <200 |

| 30EH | 1080-1130 | 10.8-11.3 | >812 | >10.2 | >2388 | >30 | 223-247 | 28-31 | <200 |

| 33EH | 1130-1170 | 11.3-11.7 | >836 | >10.5 | >2388 | >30 | 247-271 | 31-36 | <200 |

| 35EH | 1170-1220 | 11.7-12.2 | >876 | >11 | >2388 | >30 | 263-287 | 33-36 | <200 |

| 38EH | 1220-1250 | 12.2-12.5 | >899 | >11.3 | >2388 | >30 | 287-310 | 36-39 | <200 |

| 28AH | 1040-1090 | 10.4-10.9 | >787 | >9.9 | >2642 | >33 | 207-231 | 26-29 | <230 |

| 30AH | 1080-1130 | 10.8-11.3 | >819 | >10.3 | >2642 | >33 | 223-247 | 28-31 | <230 |

| 38AH | 1130-1170 | 11.3-11.7 | >843 | >10.6 | >2642 | >33 | 247-271 | 31-34 | <230 |

With 25 years of experience in manufacturing countersunk neodymium magnets, we offer more than just standard products. We can customize the size of the magnets based on your specific requirements, ensuring the perfect fit for your application.

Additionally, we provide options to customize the magnet grade and magnetization direction, giving you full control over the performance and functionality of your magnets. Whether you need these nickel coating magnets with screw holes for industrial, commercial, or personal projects, we can meet your exact needs with precision and quality.

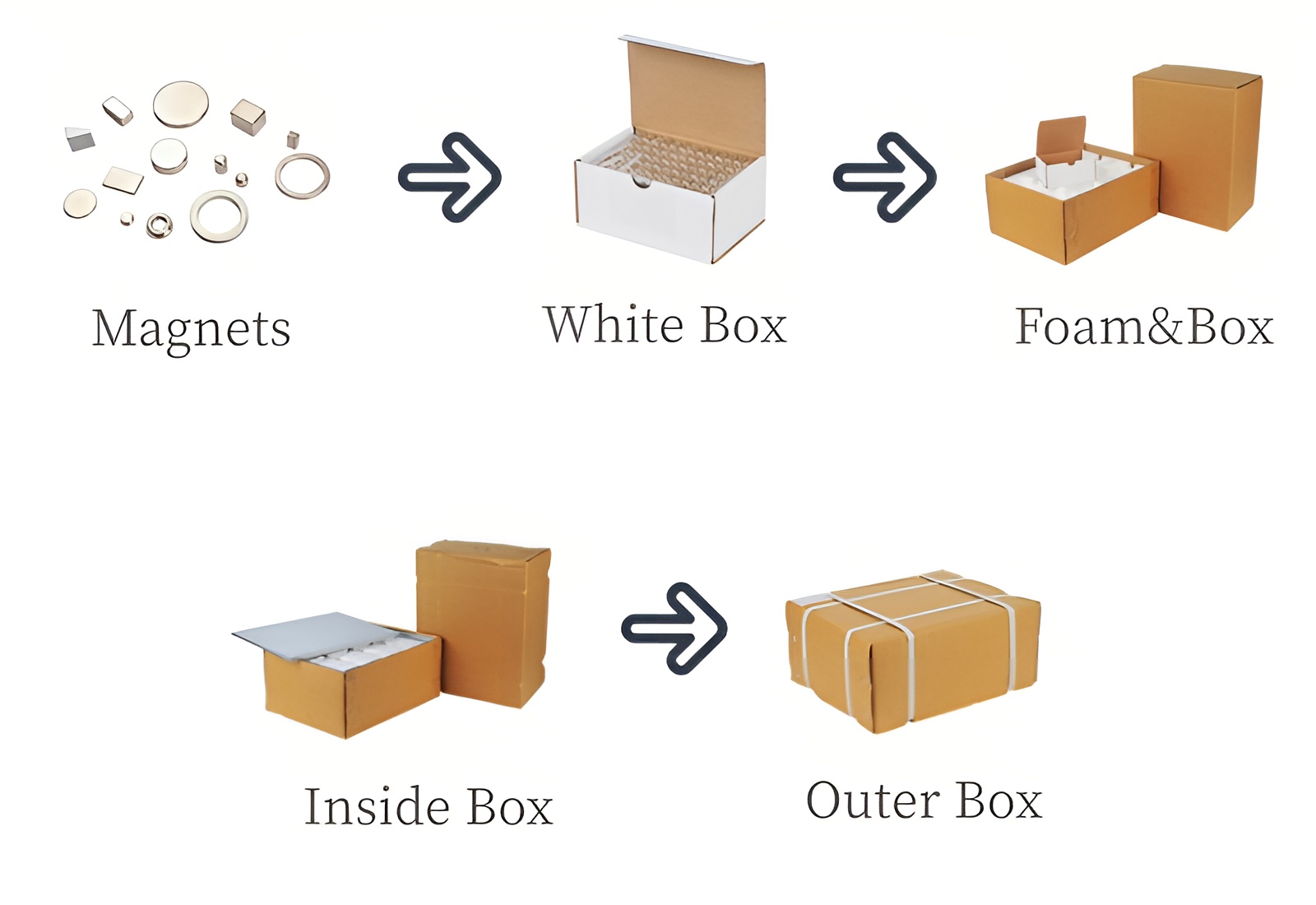

Packing&Shipping

Hi! Click one of our members below to chat on