Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

Epoxy coated block neodymium magnets are widely used in equipment that requires high magnetism and durability due to its strong magnetic properties and good corrosion resistance protection.

Color :

BlackSize :

60*20*10mm M4Order(MOQ) :

100pcsGrade :

N35-N52Material :

Neodymiun magnetCoating :

EpoxyLead Time :

3-15daysPayment :

Paypal/TT/Credit CardFactory Custom Epoxy Coated Block Neodymium Countersunk Magnet

Product Description

Dimensions: 60*20*10mm M4

Screw Size: 4mm

Material: Neodymium

Plating/Coating: Epoxy

Magnetization Direction: Axial

Warning:

Keep away from pacemakers and children.

If damaged please dispose of completely.

Customization

We are a magnet production factory engaged in the research and development, manufacturing, and sales of permanent magnets, providing customers with the highest quality service.

1.Size: Customizable according to needs.

2.Magnetic grade: The magnetic performance level of neodymium magnets, the larger the number, the stronger the magnetic performance, and the greater the suction force.

| Neodymium | Br | Hcb | Hcj | (Bh)max | Tw | ||||

| Grade | mT | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | ℃ |

| N35 | 1170-1220 | 11.7-12.2 | >868 | >10.9 | >955 | >12 | 263-287 | 33-36 | <80 |

| N38 | 1220-1250 | 12.2-12.5 | >899 | >11.3 | >955 | >12 | 287-310 | 38-39 | <80 |

| N40 | 1250-1280 | 12.5-12.8 | >907 | >11.4 | >955 | >12 | 302-326 | 38-41 | <80 |

| N42 | 1280-1320 | 12.8-13.2 | >915 | >11.5 | >955 | >12 | 318-342 | 40-43 | <80 |

| N45 | 1330-1370 | 13.3-13.7 | >915 | >11.5 | >955 | >12 | 342-367 | 41-44 | <80 |

| N48 | 1380-1420 | 13.8-14.2 | >923 | >11.6 | >955 | >12 | 366-390 | 46-49 | <80 |

| N50 | 1400-1450 | 14.0-14.5 | >796 | >10 | >876 | >11 | 382-406 | 48-49 | <80 |

| N52 | 1430-1480 | 14.3-14.8 | >796 | >10 | >876 | >11 | 398-422 | 50-53 | <80 |

| 35M | 1170-1220 | 11.7-12.2 | >868 | >10.9 | >1114 | >14 | 263-297 | 33-36 | <100 |

| 38M | 1220-1250 | 12.2-12.5 | >899 | >11.3 | >1114 | >14 | 297-310 | 36-39 | <100 |

| 40M | 1250-1280 | 12.5-12.8 | >923 | >11.6 | >1114 | >14 | 302-326 | 38-41 | <100 |

| 42M | 1280-1320 | 12.8-13.2 | >955 | >12 | >1114 | >14 | 318-342 | 40-43 | <100 |

| 48M | 1360-1430 | 13.6-14.3 | >1027 | >12.9 | >1114 | >14 | 366-390 | 46-49 | <100 |

| 50M | 1400-1450 | 14.0-14.5 | >1033 | >13 | >1114 | >14 | 382-406 | 48-51 | <100 |

| 33H | 1130-1170 | 11.3-11.7 | >836 | >10.5 | >1353 | >17 | 247-271 | 31-34 | <120 |

| 35H | 1170-1220 | 11.7-12.2 | >868 | >10.9 | >1353 | >17 | 263-287 | 33-36 | <120 |

| 38H | 1220-1250 | 12.2-12.5 | >899 | >11.3 | >1353 | >17 | 287-310 | 36-39 | <120 |

| 40H | 1250-1280 | 12.5-12.8 | >923 | >11.6 | >1353 | >17 | 302-326 | 38-41 | <120 |

| 42H | 1280-1320 | 12.8-13.2 | >955 | >12 | >1353 | >17 | 318-342 | 40-43 | <120 |

| 45H | 1300-1360 | 13.0-13.6 | >963 | >12.1 | >1353 | >17 | 326-358 | 43-46 | <120 |

| 48H | 1370-1430 | 13.7-14.3 | >995 | >12 | >1353 | >17 | 366-390 | 46-49 | <120 |

| 30SH | 1080-1130 | 10.8-11.3 | >804 | >10.1 | >1592 | >20 | 223-247 | 28-31 | <150 |

| 33SH | 1130-1170 | 10.3-11.7 | >844 | >10.6 | >1592 | >20 | 247-271 | 31-34 | <150 |

| 35SH | 1170-1220 | 11.7-12.2 | >876 | >11 | >1592 | >20 | 263-287 | 33-36 | <150 |

| 38SH | 1220-1250 | 12.2-12.5 | >907 | >11.4 | >1592 | >20 | 287-310 | 36-39 | <150 |

| 40SH | 1240-1280 | 12.5-12.8 | >939 | >11.8 | >1592 | >20 | 302-326 | 36-41 | <150 |

| 42SH | 1280-1320 | 12.8-13.2 | >987 | >12.4 | >1592 | >20 | 318-342 | 40-43 | <150 |

| 45SH | 1320-1380 | 13.2-13.8 | >1003 | >12.6 | >1592 | >20 | 342-366 | 43-46 | <150 |

| 28UH | 1020-1080 | 10.2-10.8 | >764 | >9.6 | >1990 | >25 | 207-231 | 26-29 | <180 |

| 30UH | 1080-1130 | 10.8-11.3 | >812 | >10.2 | >1990 | >25 | 223-247 | 28-31 | <180 |

| 33UH | 1130-1170 | 11.3-11.7 | >852 | >10.7 | >1990 | >25 | 247-271 | 31-36 | <180 |

| 35UH | 1170-1220 | 11.8-12.2 | >860 | >10.8 | >1990 | >25 | 263-287 | 33-36 | <180 |

| 38UH | 1220-1250 | 12.2-12.5 | >876 | >11 | >1990 | >25 | 287-310 | 36-39 | <180 |

| 40UH | 1250-1280 | 12.5-12.8 | >899 | >11.3 | >1990 | >25 | 302-326 | 31-41 | <180 |

| 28EH | 1040-1090 | 10.4-10.9 | >780 | >9.8 | >2388 | >30 | 207-231 | 26-29 | <200 |

| 30EH | 1080-1130 | 10.8-11.3 | >812 | >10.2 | >2388 | >30 | 223-247 | 28-31 | <200 |

| 33EH | 1130-1170 | 11.3-11.7 | >836 | >10.5 | >2388 | >30 | 247-271 | 31-36 | <200 |

| 35EH | 1170-1220 | 11.7-12.2 | >876 | >11 | >2388 | >30 | 263-287 | 33-36 | <200 |

| 38EH | 1220-1250 | 12.2-12.5 | >899 | >11.3 | >2388 | >30 | 287-310 | 36-39 | <200 |

| 28AH | 1040-1090 | 10.4-10.9 | >787 | >9.9 | >2642 | >33 | 207-231 | 26-29 | <230 |

| 30AH | 1080-1130 | 10.8-11.3 | >819 | >10.3 | >2642 | >33 | 223-247 | 28-31 | <230 |

| 38AH | 1130-1170 | 11.3-11.7 | >843 | >10.6 | >2642 | >33 | 247-271 | 31-34 | <230 |

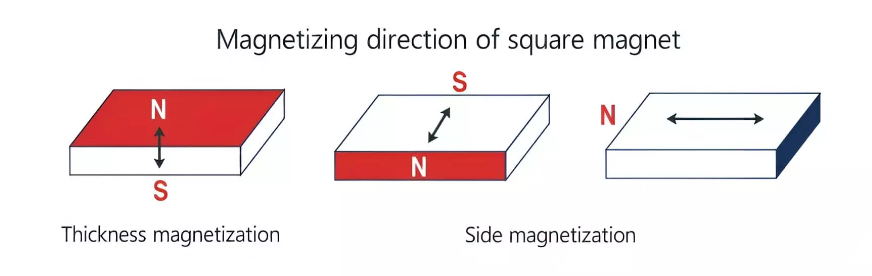

3.Magnetization direction: The magnetization direction determines the distribution and strength of the magnetic field. When multiple magnets interact, their magnetization direction also affects the attraction or repulsion between them.

4.Coatings: Magnetic coating is a thin layer of metal or alloy coating that covers the surface of a magnet.Its main function is to protect the magnet from corrosion and enhance its wear resistance.

Main Features & Advantages

Powerful magnetism:

The raw material for corrosion resistant square countersunk magnets is neodymium magnets, which are currently the strongest permanent magnets with very high energy density and high coercivity.

Epoxy coating:

Epoxy coating can effectively prevent corrosion of magnets when exposed to humid environments. The epoxy coating of the strong adhesion countersunk block magnet can provide a durable protective layer to protect the magnet from oxidation.It can also improve its impact resistance to a certain extent, reducing scratches and wear on the surface of the magnet.

Appearance:

The coating is usually black or gray, which has a good visual effect and can be customized in color according to customer requirements.

Environmentally friendly:

Epoxy coatings are typically non-toxic and meet many environmental requirements, making them suitable for industries that require compliance with environmental protection standards.

Widely used:

Epoxy coated block countersunk magnets are suitable for many industrial applications,such as:

1.Medical equipment: such as magnetic field sources in MRI equipment.

2. Electronic devices: used in small electronic devices such as hard drives and speakers.

3. Wind power generation: power generation system used for wind turbines.

4. Home appliances: such as tools holding or used in DIY items.

5.Automotive industry: used for electric motors, sensors, speakers, etc.

Packing&Shipping

Hi! Click one of our members below to chat on