Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

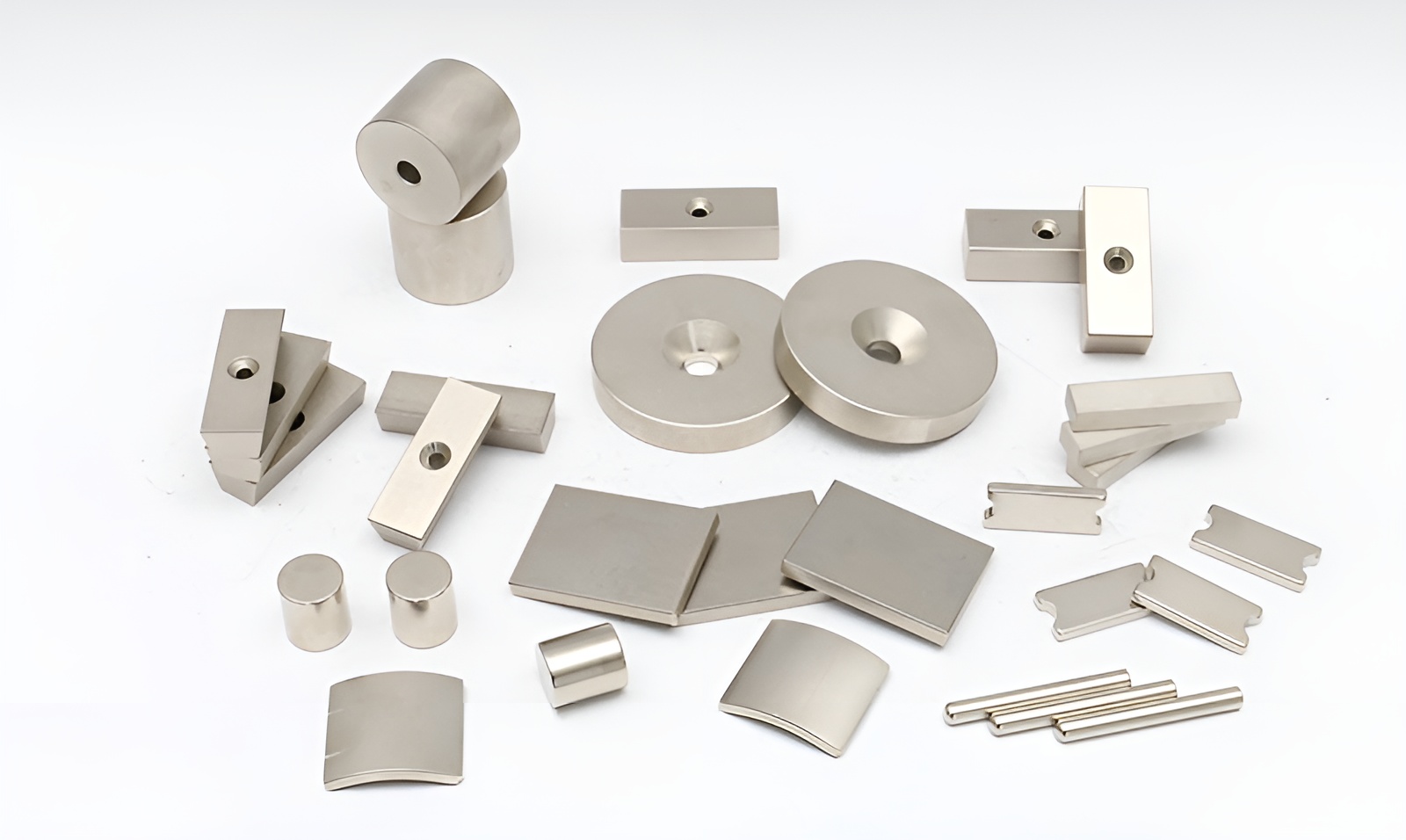

Powerful neodymium magnets are special magnets with strong magnetic properties and adsorption force. They are also commonly used magnets and can be seen everywhere in daily life and industrial fields. In order to ensure that the quality and performance of powerful magnets meet standards, strict quality testing is required. The following are several common quality inspection methods for powerful magnets:

Magnetic detection: Magnetism is one of the core properties of powerful magnets. Use a magnetometer or gaussmeter to measure the magnetic field strength of neodymium magnets. A high-quality neodymium magnet should have a high magnetic field strength, which can help determine whether the magnet meets specified magnetic requirements.

Magnetic adsorption force test: The adsorption force of powerful magnets is an important indicator of its performance. The adhesion force of powerful magnets can be measured using a special magnetic tester or scale. The test method can be to directly measure the maximum adsorption force between the magnet and the steel plate, or it can be evaluated by measuring the adsorption force between the magnet and the steel ball.

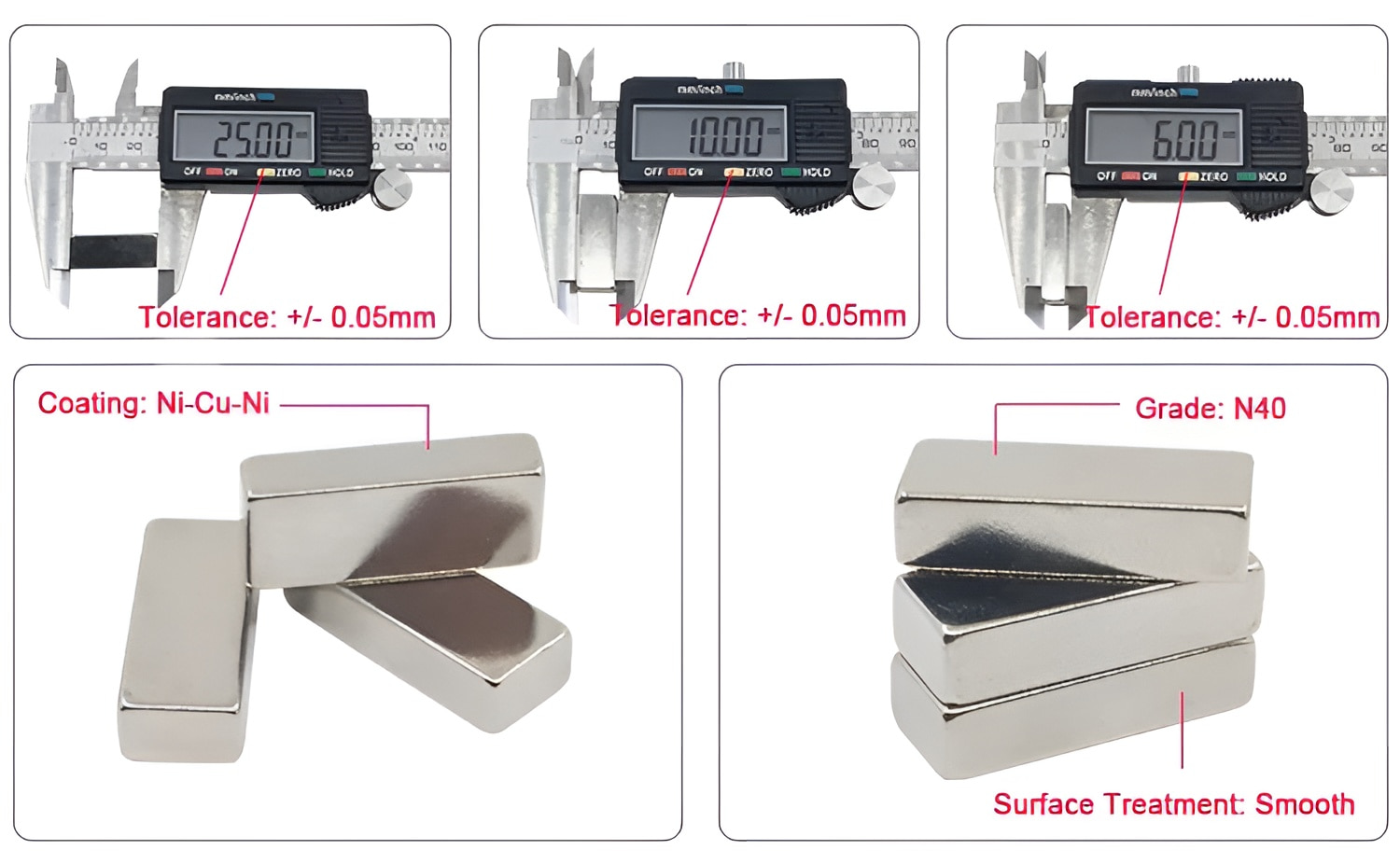

Appearance inspection: Check the appearance of neodymium magnets. A high-quality neodymium magnet should have a smooth surface and uniform color. Check the appearance quality of the magnet by visual inspection and touch, including surface flatness, gloss, color and shape, etc. Any surface defects, cracks or foreign matter may affect the performance and lifespan of the magnet.

Chemical composition analysis: Powerful magnets are usually made of a variety of metals and alloys. Through chemical composition analysis instruments, the content of various elements in the magnet can be detected to ensure that its chemical composition meets standard requirements.

Dimensional measurements: It is very important to measure the dimensions and geometric parameters of powerful magnets. Use measuring tools (such as calipers, micrometers) to measure the diameter, height and other dimensional parameters of the magnet to ensure that it meets the specified size requirements. High-quality neodymium magnets should have precise dimensions, and the tolerance generally remains within the range of ±0.05mm.

Overall, quality inspection of strong powerful ndfeb magnets is a critical step to ensure their performance and reliability. By using professional testing equipment and methods, the magnet's magnetism, adsorption force, appearance, size, chemical composition and temperature characteristics can be comprehensively tested and evaluated. This helps ensure that powerful magnets comply with relevant standards and requirements and guarantee their reliability and durability in a variety of applications.

Hi! Click one of our members below to chat on