Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

Inventory strategy plays a crucial role in controlling the procurement costs of neodymium magnets, especially when sourcing from overseas suppliers. For buyers who rely on a stable supply, predictable pricing, and on-time delivery, planning inventory in advance is often more cost-effective than placing urgent orders.

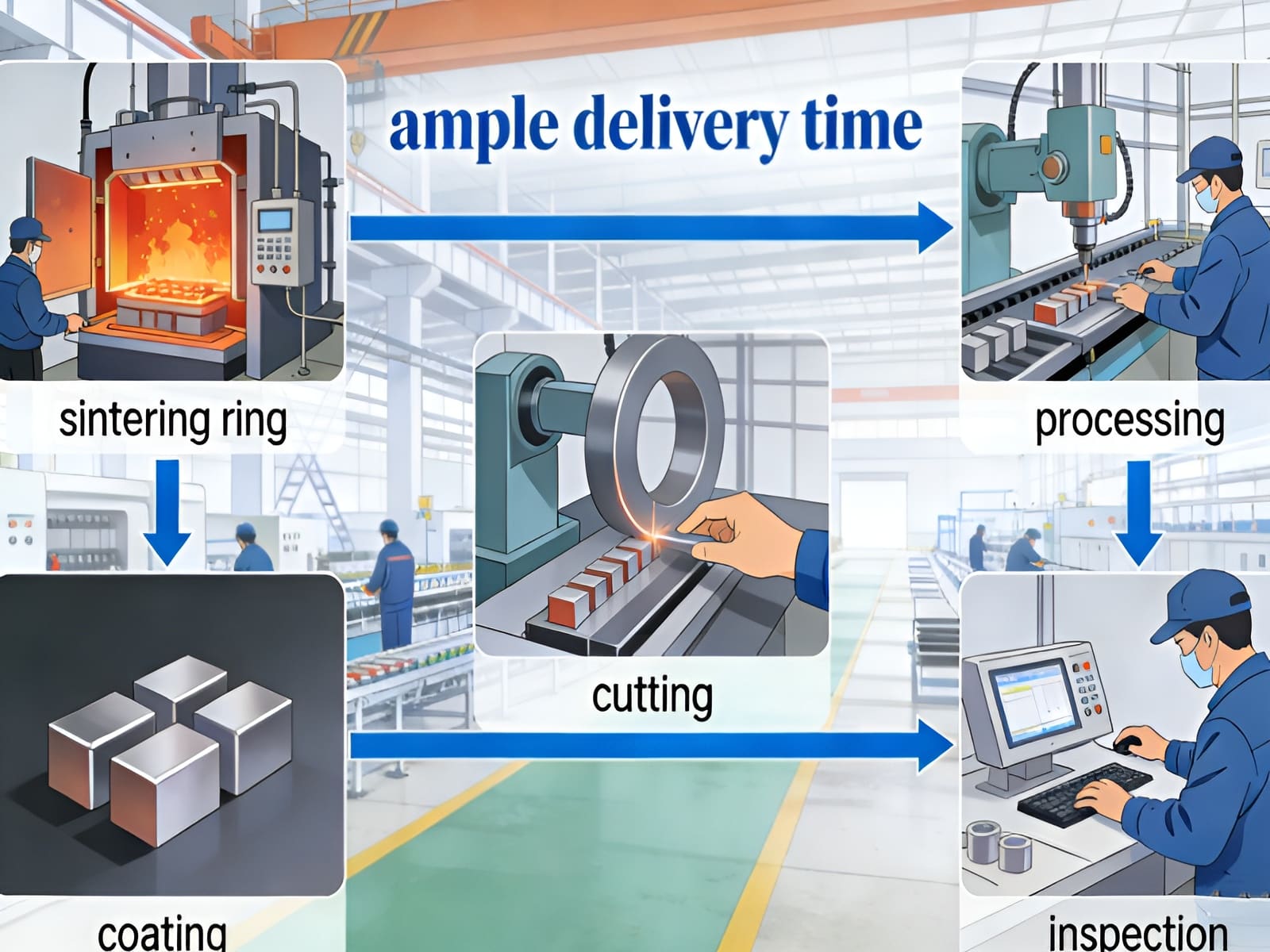

One of the most overlooked cost drivers in magnet procurement is time. The process of producing neodymium magnets involves multiple steps, including sintering, machining, coating, and quality inspection. With sufficient lead time, factories can efficiently schedule production, optimize material usage, and offer more competitive pricing. Conversely, last-minute orders often result in higher unit costs due to expedited production, limited raw material availability, or priority scheduling fees.

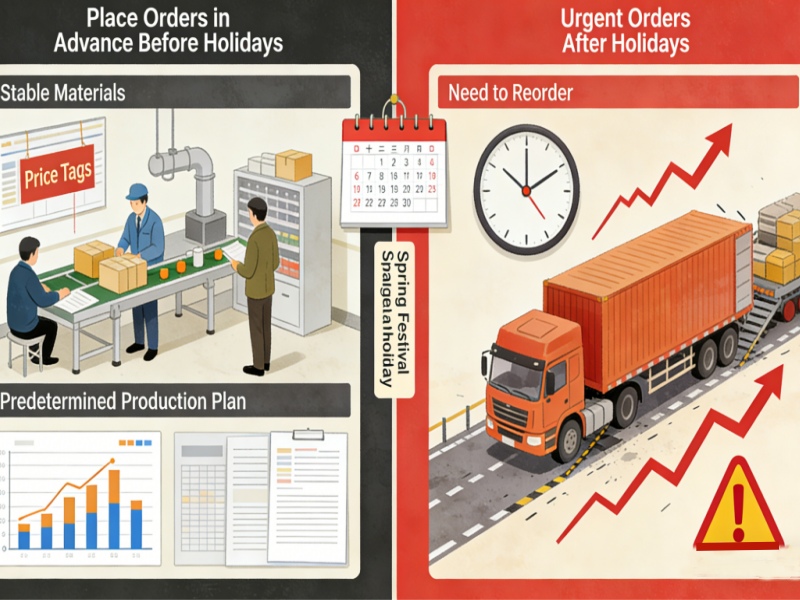

This is particularly important as the Chinese New Year approaches. During this period, many magnet manufacturers cease production for at least nine days, and in some cases, the shutdown may be longer due to extended holidays or delays in workers returning to work. Before the holiday, factories typically experience a surge in orders, which can lead to extended lead times, reduced customization flexibility, and strained capacity.

From a cost perspective, buyers who finalize their procurement plans before the holiday can reap several benefits. First, Ndfeb magnet raw material prices are usually more stable, while prices may fluctuate after the holiday due to supply chain disruptions or increased demand. Second, booking production slots in advance helps avoid congestion and reduces the risk of delays that could impact downstream projects or sales plans.

Inventory planning also impacts logistics costs. Placing orders in advance allows for better shipping options, whether by sea or air, helping buyers avoid additional freight charges incurred due to urgent situations. This is especially important for international buyers, as shipping delays during the holiday period can extend overall delivery times by several weeks.

For magnet buyers in industries such as industrial manufacturing, packaging, consumer electronics, or magnetic components, a proactive inventory strategy ensures continuity of supply while controlling procurement costs. Instead of reacting to shortages, anticipating demand and coordinating with suppliers in advance of major production disruptions leads to long-term cost savings and operational stability.

As a rare earth magnet supplier, we encourage our customers to review their Q1 inventory needs early and communicate upcoming requirements before the Chinese New Year. Strategic planning not only secures pricing and delivery times but also strengthens supplier partnerships and supply chain resilience. Advance preparation remains one of the simplest and most effective ways to reduce magnet procurement costs and ensure a reliable supply.

Hi! Click one of our members below to chat on