Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

Magnetic materials usuallay contain more iron, and everyone knows that iron is easy to be oxidized, and then it is easier to react with water. Therefore, magnetic materials with very high iron content are very easy to be corroded. At the same time, various elements used in other different types of permanent magnets, such as nickel, cobalt, gadolinium, dysprosium, etc., will also have an impact on the corrosion resistance of the magnet.

When we need to develop magnetic components, the corrosion resistance of customized different permanent magnets is a key factor to take into account. Next, we will discuss and fully understand the corrosion resistance of different magnetic materials.

1.Ndfeb Neodymium Magnet

At present, high-performance permanent NdFeb magnet on the market, its iron content is as high as 64%, so it is inevitable that they are vulnerable to corrosion in a humid environment. At present, science and technology have found that adding a small amount of rare earth elements in NdFeb alloy can effectively improve its corrosion resistance and magnetism.

In addition, in the processing of neodymium magnets, coating is performed before use. Among them, the most common coating is nickel-copper-nickel (there may be some people wondering why it is not coated with one or two layers of nickel, adding copper in the middle is to make the nickel coating more cohesive), there are other options, such as galvanized, gold plated, silver plated, epoxy plated, and so on.

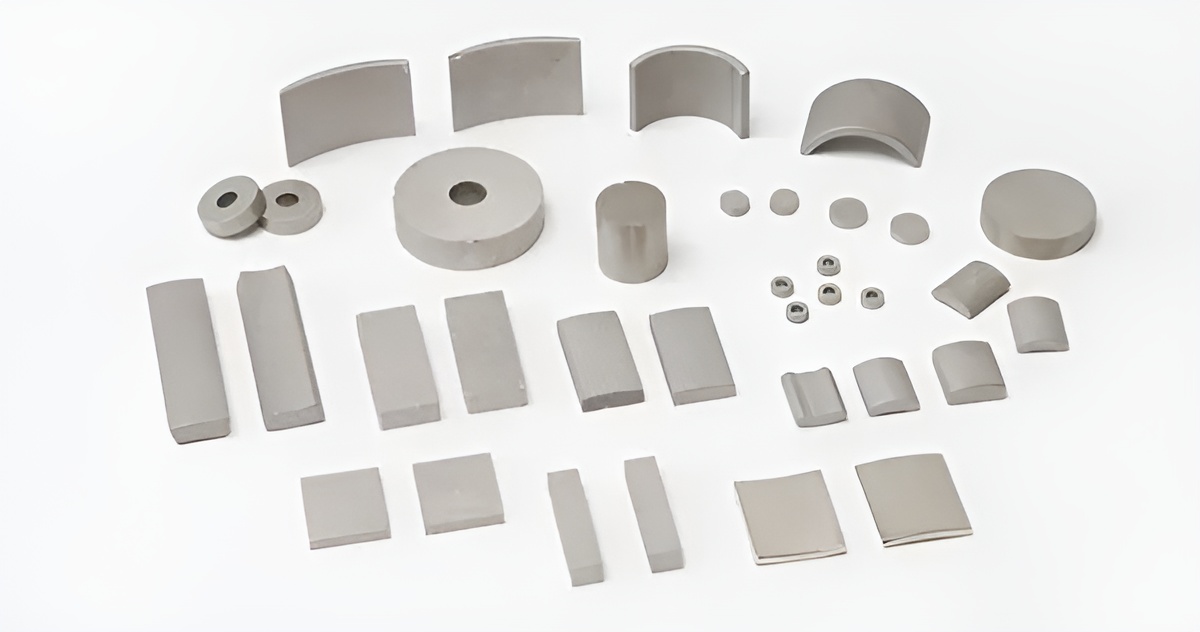

2. Samarium cobalt magnet

Samarium cobalt magnets and NdFeb magnets belong to the rare earth series, but it has cobalt, instead a certain amount of iron, cobalt does not react with water, even in the case of uncoated also has a certain corrosion resistance. Samarium-cobalt magnets are therefore widely used in Marine and offshore applications. In addition, customized samarium-cobalt magnets will also be coated, mainly for aesthetic purposes or for application-specific reasons, such as enhancing adhesion or sterility.

3. Ferrite magnet

Ferrite magnet, also known as a ceramic magnet, is a permanent magnet made from a mixture of iron oxide and other metallic elements. Because iron oxide is not made to react with water, it will not be corroded even if submerged in water, so strong powerful ferrite magnets are rarely coated. Compared with rare earth magnets such as NdFeb and samarium cobalt, it is relatively cheap and has moderate magnetic strength. But because ferrite magnet is a dusty material, some applications require some surface treatment to avoid dust diffusion.

Different types of permanent magnets have their own strengths and weaknesses, of course, choosing the right magnet for a specific occasion is the most appropriate approach. If there are questions and knowledge you want to know, please contact us professional manufacturers.

Hi! Click one of our members below to chat on