Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

This versatile rare earth countersunk magnets can be used as cabinet magnet, locker magnet, refrigerator magnet, calendar magnet, map magnet, kitchen magnet...

Color :

BlackSize :

0.98'' x 0.12''Order(MOQ) :

100pcsSample :

FreeLead Time :

3-15daysPayment :

Paypal/TT/Credit CardWaterproof Epoxy Coating Round Countersunk Hole Neodymium Magnet

Product Description

Dimensions: 0.98'' x 0.12''

Screw Size : 0.2''

Tolerances: ±0.004" x ±0.004"

Material: NdFeB

Plating/Coating: Epoxy

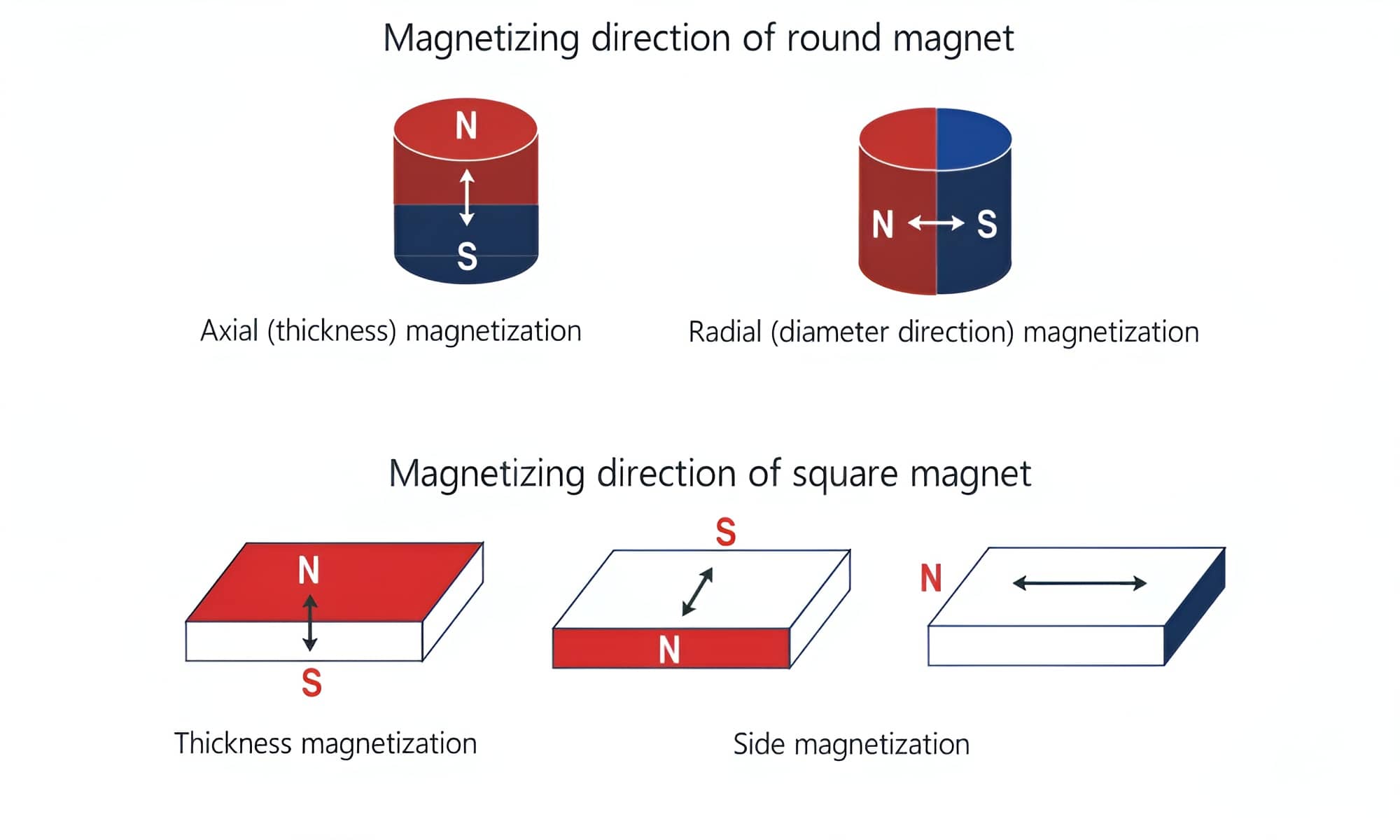

Magnetization Direction: Axial (Poles on Flat Ends)

Specification

| Neodymium | Br | Hcb | Hcj | (Bh)max | Tw | ||||

| Grade | mT | kGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | ℃ |

| N35 | 1170-1220 | 11.7-12.2 | >868 | >10.9 | >955 | >12 | 263-287 | 33-36 | <80 |

| N38 | 1220-1250 | 12.2-12.5 | >899 | >11.3 | >955 | >12 | 287-310 | 38-39 | <80 |

| N40 | 1250-1280 | 12.5-12.8 | >907 | >11.4 | >955 | >12 | 302-326 | 38-41 | <80 |

| N42 | 1280-1320 | 12.8-13.2 | >915 | >11.5 | >955 | >12 | 318-342 | 40-43 | <80 |

| N48 | 1380-1420 | 13.8-14.2 | >923 | >11.6 | >955 | >12 | 366-390 | 46-49 | <80 |

| N50 | 1400-1450 | 14.0-14.5 | >796 | >10 | >876 | >11 | 382-406 | 48-49 | <80 |

| N52 | 1430-1480 | 14.3-14.8 | >796 | >10 | >876 | >11 | 398-422 | 50-53 | <80 |

| 35M | 1170-1220 | 11.7-12.2 | >868 | >10.9 | >1114 | >14 | 263-297 | 33-36 | <100 |

| 38M | 1220-1250 | 12.2-12.5 | >899 | >11.3 | >1114 | >14 | 297-310 | 36-39 | <100 |

| 40M | 1250-1280 | 12.5-12.8 | >923 | >11.6 | >1114 | >14 | 302-326 | 38-41 | <100 |

| 42M | 1280-1320 | 12.8-13.2 | >955 | >12 | >1114 | >14 | 318-342 | 40-43 | <100 |

| 48M | 1360-1430 | 13.6-14.3 | >1027 | >12.9 | >1114 | >14 | 366-390 | 46-49 | <100 |

| 50M | 1400-1450 | 14.0-14.5 | >1033 | >13 | >1114 | >14 | 382-406 | 48-51 | <100 |

| 33H | 1130-1170 | 11.3-11.7 | >836 | >10.5 | >1353 | >17 | 247-271 | 31-34 | <120 |

| 35H | 1170-1220 | 11.7-12.2 | >868 | >10.9 | >1353 | >17 | 263-287 | 33-36 | <120 |

| 38H | 1220-1250 | 12.2-12.5 | >899 | >11.3 | >1353 | >17 | 287-310 | 36-39 | <120 |

| 40H | 1250-1280 | 12.5-12.8 | >923 | >11.6 | >1353 | >17 | 302-326 | 38-41 | <120 |

| 42H | 1280-1320 | 12.8-13.2 | >955 | >12 | >1353 | >17 | 318-342 | 40-43 | <120 |

| 45H | 1300-1360 | 13-13.6 | >963 | >12.1 | >1353 | >17 | 326-358 | 43-46 | <120 |

| 48H | 1370-1430 | 13.7-14.3 | >995 | >12 | >1353 | >17 | 366-390 | 46-49 | <120 |

| 30SH | 1080-1130 | 10.8-11.3 | >804 | >10.1 | >1592 | >20 | 223-247 | 28-31 | <150 |

| 33SH | 1130-1170 | 10.3-11.7 | >844 | >10.6 | >1592 | >20 | 247-271 | 31-34 | <150 |

| 35SH | 1170-1220 | 11.7-12.2 | >876 | >11 | >1592 | >20 | 263-287 | 33-36 | <150 |

| 38SH | 1220-1250 | 12.2-12.5 | >907 | >11.4 | >1592 | >20 | 287-310 | 36-39 | <150 |

| 40SH | 1240-1280 | 12.5-12.8 | >939 | >11.8 | >1592 | >20 | 302-326 | 36-41 | <150 |

| 42SH | 1280-1320 | 12.8-13.2 | >987 | >12.4 | >1592 | >20 | 318-342 | 40-43 | <150 |

| 45SH | 1320-1380 | 13.2-13.8 | >1003 | >12.6 | >1592 | >20 | 342-366 | 43-46 | <150 |

| 28UH | 1020-1080 | 10.2-10.8 | >764 | >9.6 | >1990 | >25 | 207-231 | 26-29 | <180 |

| 30UH | 1080-1130 | 10.8-11.3 | >812 | >10.2 | >1990 | >25 | 223-247 | 28-31 | <180 |

| 33UH | 1130-1170 | 11.3-11.7 | >852 | >10.7 | >1990 | >25 | 247-271 | 31-36 | <180 |

| 35UH | 1170-1220 | 11.8-12.2 | >860 | >10.8 | >1990 | >25 | 263-287 | 33-36 | <180 |

| 38UH | 1220-1250 | 12.2-12.5 | >876 | >11 | >1990 | >25 | 287-310 | 36-39 | <180 |

| 40UH | 1250-1280 | 12.5-12.8 | >899 | >11.3 | >1990 | >25 | 302-326 | 31-41 | <180 |

| 28EH | 1040-1090 | 10.4-10.9 | >780 | >9.8 | >2388 | >30 | 207-231 | 26-29 | <200 |

| 30EH | 1080-1130 | 10.8-11.3 | >812 | >10.2 | >2388 | >30 | 223-247 | 28-31 | <200 |

| 33EH | 1130-1170 | 11.3-11.7 | >836 | >10.5 | >2388 | >30 | 247-271 | 31-36 | <200 |

| 35EH | 1170-1220 | 11.7-12.2 | >876 | >11 | >2388 | >30 | 263-287 | 33-36 | <200 |

| 38EH | 1220-1250 | 12.2-12.5 | >899 | >11.3 | >2388 | >30 | 287-310 | 36-39 | <200 |

| 28AH | 1040-1090 | 10.4-10.9 | >787 | >9.9 | >2642 | >33 | 207-231 | 26-29 | <230 |

| 30AH | 1080-1130 | 10.8-11.3 | >819 | >10.3 | >2642 | >33 | 223-247 | 28-31 | <230 |

| 38AH | 1130-1170 | 11.3-11.7 | >843 | >10.6 | >2642 | >33 | 247-271 | 31-34 | <230 |

Three layers of electroplated axial magnetization, the best black epoxy coating can be used to prevent rust and provide a smooth surface, greatly increasing the life of the disc magnet with countersunk hole.

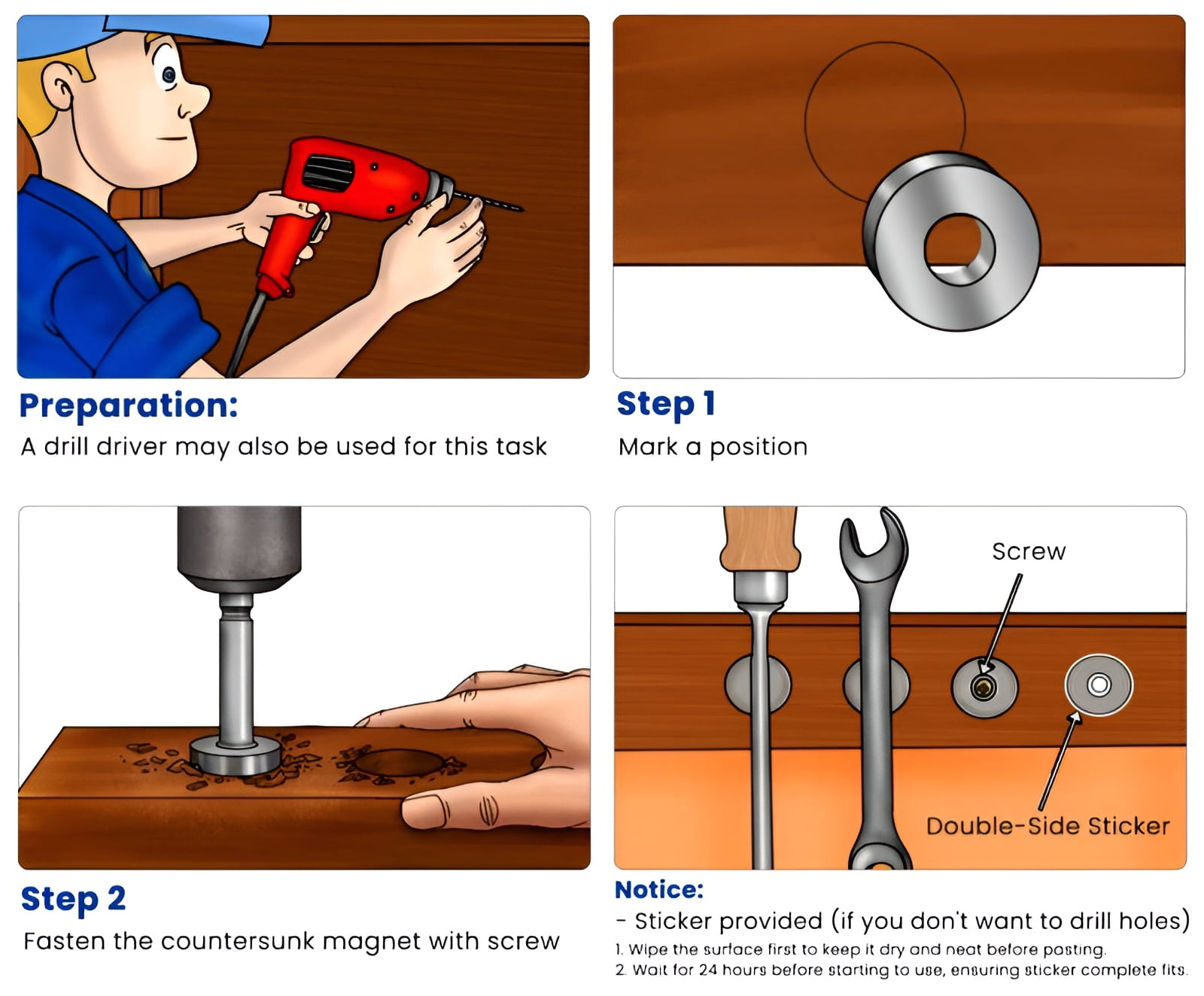

How To Use

Epoxy coating countersunk magnets can directly absorbed on magnetic material and can be fixed on non-magnetic material with screws. Sturdy and reliable.

If you want to separate them, try to slide, but don't pull. Be careful with your fingers when you separating.

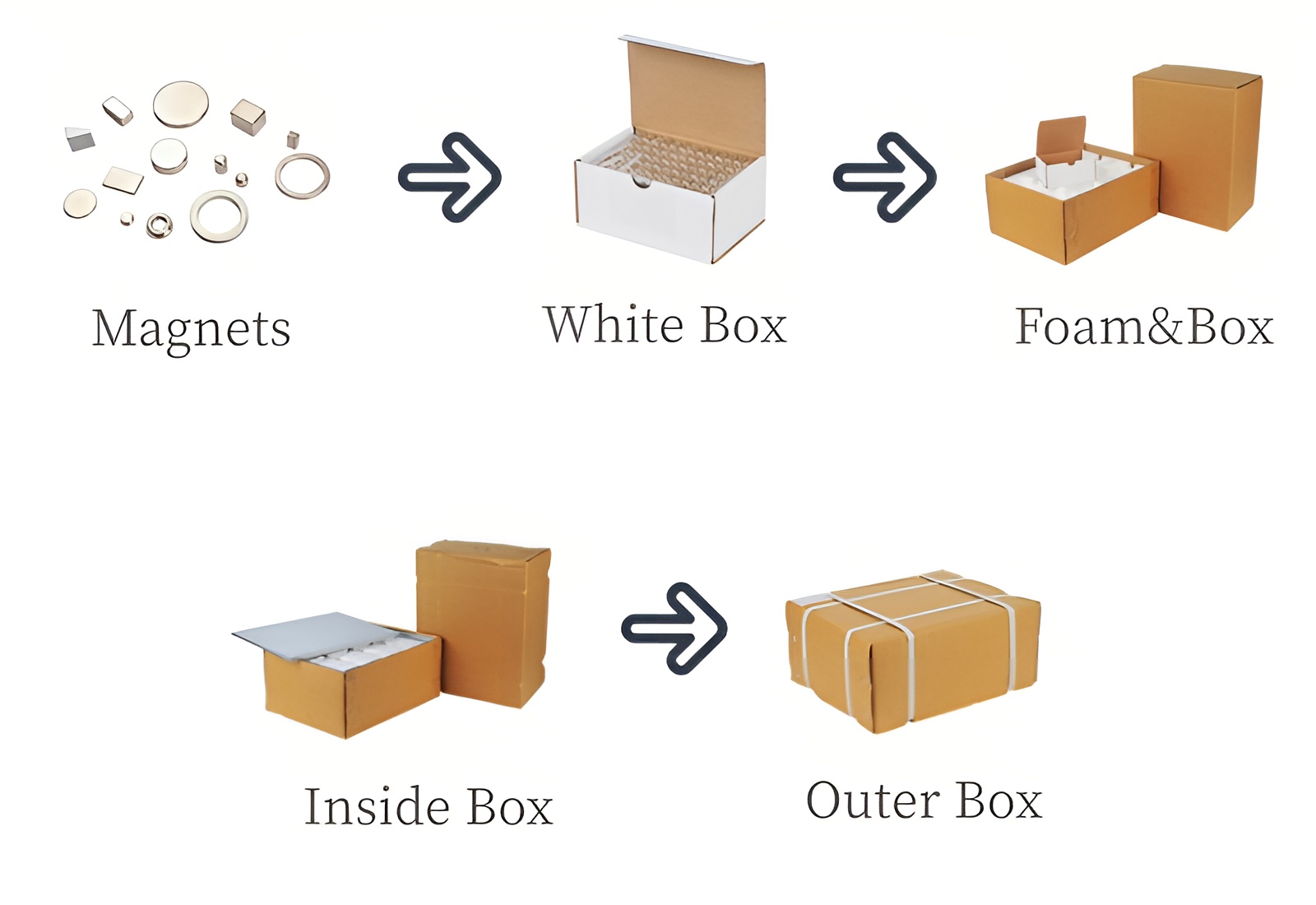

Packing&Shipping

Hi! Click one of our members below to chat on