Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

In 2025, the global magnet industry will enter a new era of environmental responsibility. As sustainability becomes a key focus in industrial manufacturing, new environmental standards for neodymium magnet production are being implemented to meet domestic and international regulations. Europe's Extended Producer Responsibility (EPR) policy is setting a new benchmark for the entire supply chain, from raw materials to final product disposal.

EPR regulations, already adopted by many EU countries (such as Germany, France, and the Netherlands), require manufacturers and importers to assume full responsibility for the environmental impact of their products throughout their lifecycle. This means that companies involved in the production or sale of magnetic components must ensure that their products are recyclable, properly labeled, and produced with minimal environmental impact. For magnet manufacturers, this is more than just a compliance issue; it presents an opportunity for innovation.

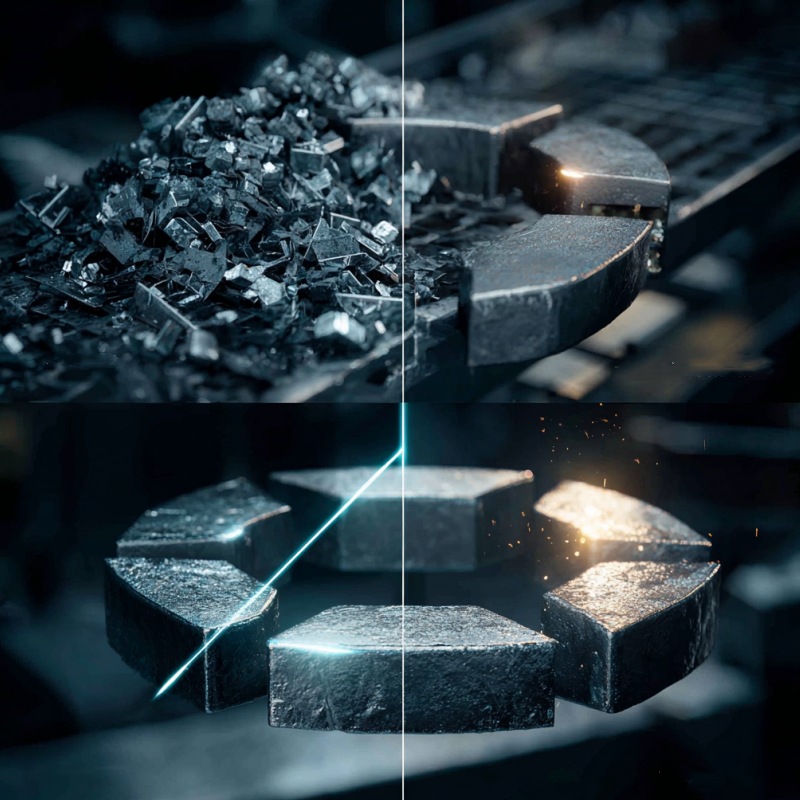

At Hefei Super Electronics, we have already begun adapting to these new standards. Our production facilities utilize cleaner neodymium magnets sintering processes, waste reduction systems, and energy-efficient coating technologies to reduce emissions and improve material utilization. Our closed-loop recycling system for neodymium and other rare earth materials enables us to recover valuable metals from production waste, reducing our reliance on newly mined resources. In addition, the new standard encourages the use of environmentally friendly coatings, replacing traditional electroplating materials that may contain hazardous substances. Our latest epoxy and nickel coatings are RoHS-compliant and comply with EU environmental directives, ensuring product durability and ecological safety.

These efforts not only align with EPR requirements but also reflect the growing expectations of global customers, who value transparency and sustainable sourcing. European distributors and OEM customers are increasingly seeking partners who can demonstrate environmental compliance—not only to meet legal requirements but also to enhance their own brand image and ESG goals.

As more countries adopt similar EPR frameworks, the magnet industry is likely to shift toward more environmentally friendly materials, efficient recycling systems, and digital traceability of production. Hefei Chao Electronics is committed to leading this transformation by integrating advanced manufacturing with sustainable practices.

We integrate environmental awareness into every step of magnet production, from material selection to shipping, aiming to create a future where high performance permanent magnets coexist with environmental responsibility—driving innovation while protecting our planet.

Hi! Click one of our members below to chat on