Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

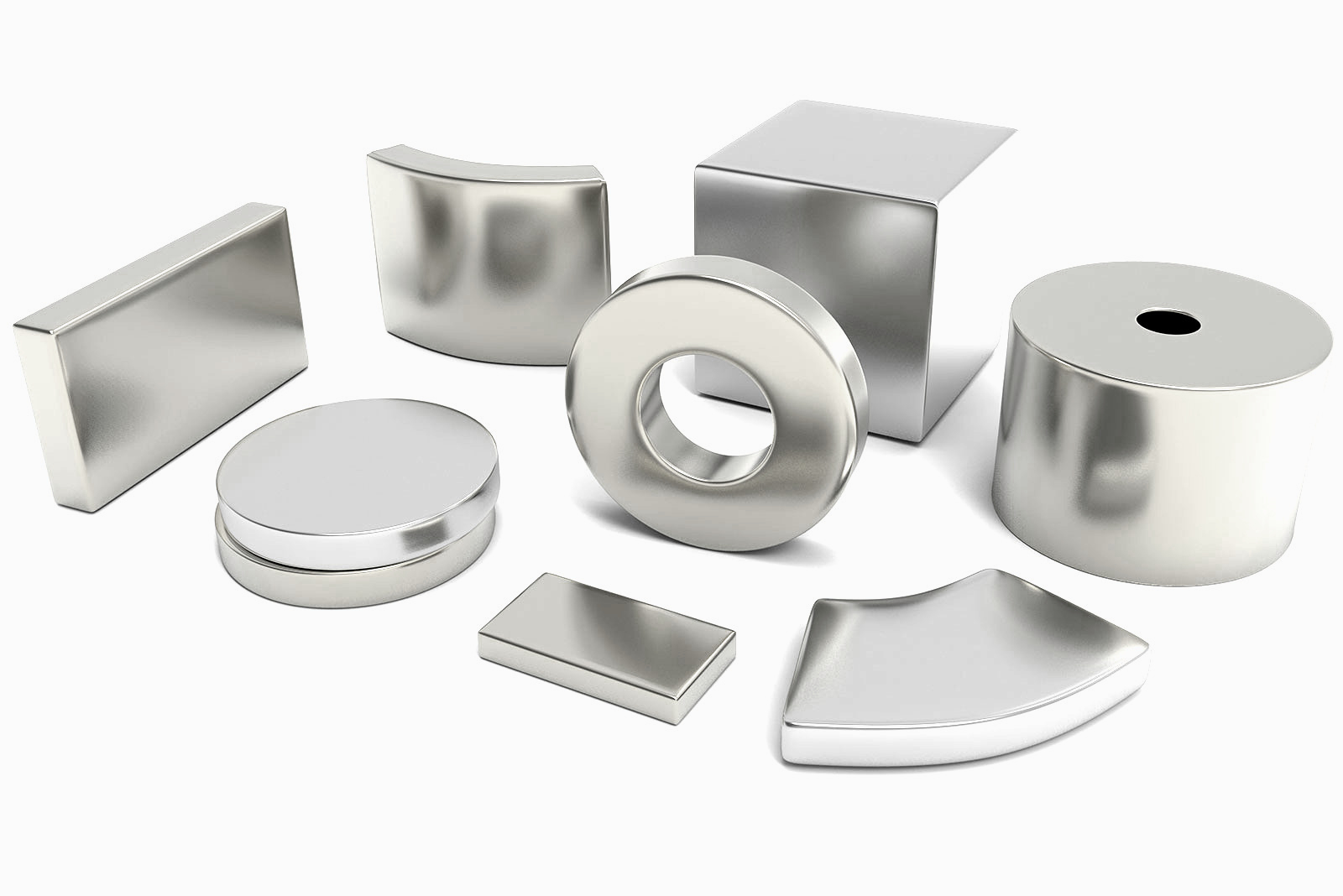

Block neodymium magnets are versatile, with uses ranging from industrial applications to countless personal projects, offering strong performance and endless possibilities.

Size :

0.59'' x 0.39'' x 0.39''Color :

SilveryOrder(MOQ) :

100PCSGrade :

N42Sample :

FreeLead Time :

3-15daysPayment :

Paypal/TT/Credit CardHigh Pulling Force N42 NdFeB Block Magnets

Product Description

Length: 0.59 inch (15 mm)

Width: 0.39 inch (10 mm)

Thickness: 0.39 inch (10 mm)

Material: NdFeB Magnet

Magnetic Grade: N42

Tolerance: ± 0.05mm

Plating/Coating: Ni-Cu-Ni (Nickel)

Magnetization Direction: Axial (Flat end magnetic pole)

Warning:

These magnets are extremely powerful and must be handled with care to avoid injuries such as pinching or breakage. Keep them away from children and electronic devices to prevent accidents or damage.

Square nickel plated strong magnetic neodymium magnet is a very strong magnet, mainly made of three materials: neodymium, iron, and boron. Its magnetic force is particularly strong, much stronger than ordinary magnets. It has a square shape and is coated with three layers of Ni+Cu+Ni on the surface, which looks shiny. It can prevent rust and make it more durable by isolating water vapor and chemicals.

Rare earth NdFeB magnet has a very strong suction force and is suitable for use in places that require strong magnetic force, such as motors, speakers, sensors, magnetic tools, and some medical equipment. Because of its good performance and durability, it can be seen in many high-tech products and industrial equipments, and become a very important material.

Support Customization

Permanent neodymium magnets can be customized in shapes, sizes, magnetic force grade, magnetization directions, and coatings to meet diverse needs and flexibly adapt to your specific application scenarios.

Neodymium magnet (NdFeB), as a high performance permanent magnet material, can be processed round, square, ring, arc and other special shapes. We can customize neodymium magnets through cutting, grinding, drilling and other processes based on the design drawings provided by customers to meet various need and performance requirements.

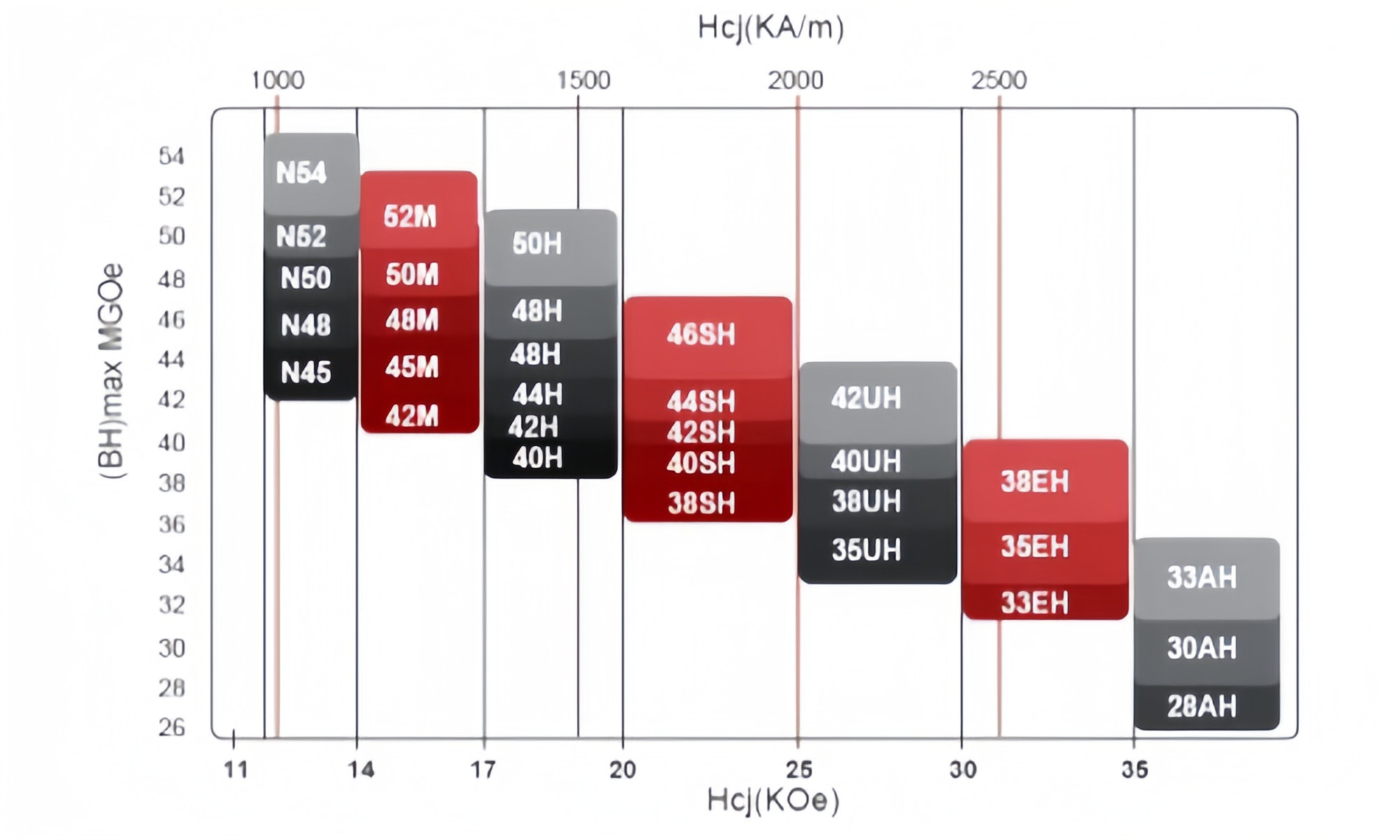

Neodymium magnet (NdFeB) has a magnetic grade from N35 to N52. The larger the number, the stronger the magnetic force.

In addition, the suffix letters (such as H, SH, UH, EH,AH) indicate the maximum operating temperature, ranging from 80℃ to 200℃, and are suitable for different temperature environments. Selecting appropriate grades and suffixes according to specific needs can ensure the best performance, cost and durability of neodymium magnets.

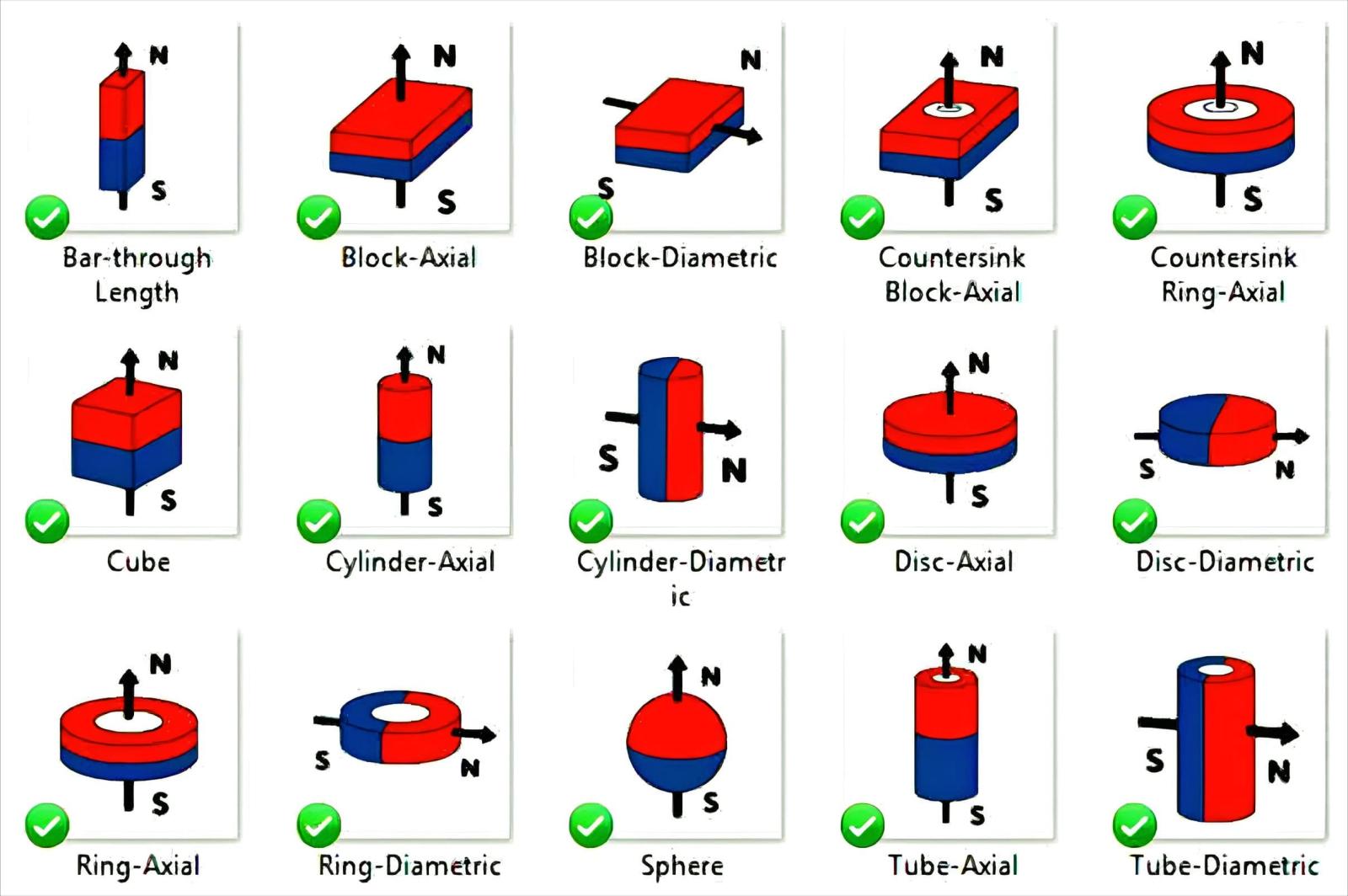

The magnetization direction of neodymium magnet determines its magnetic field distribution. The common magnetization directions include axial magnetization (magnetic field along the thickness direction) and radial magnetization (magnetic field along the diameter direction). The choice of magnetization direction depends on the specific application requirements.

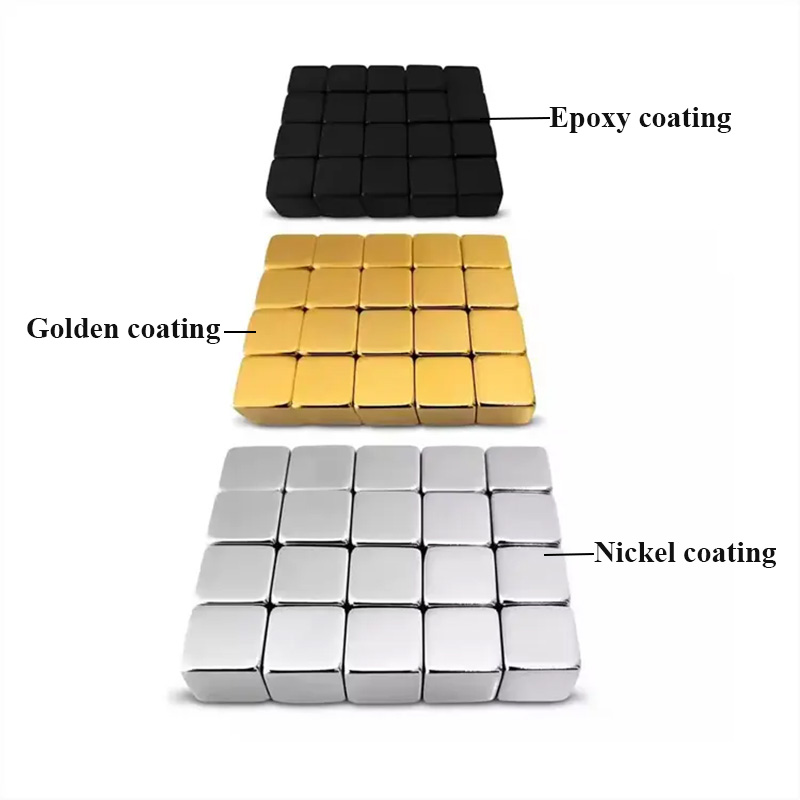

Neodymium magnets are prone to rust and corrosion, so a protective coating is usually added on the surface. Common coatings include:

--Nickel coating: silver white, good rust prevention effect, beautiful appearance, is the most commonly used coating.

--Epoxy resin coating: black, strong corrosion resistance, suitable for wet or special environment.

--Gold coating: golden yellow, good rust prevention performance and beautiful, but the cost is high, and it is mostly used for high-end products.

When selecting the coating, it mainly depends on the use environment (such as humidity, temperature) and cost.

Packing&Shipping

Hi! Click one of our members below to chat on