Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

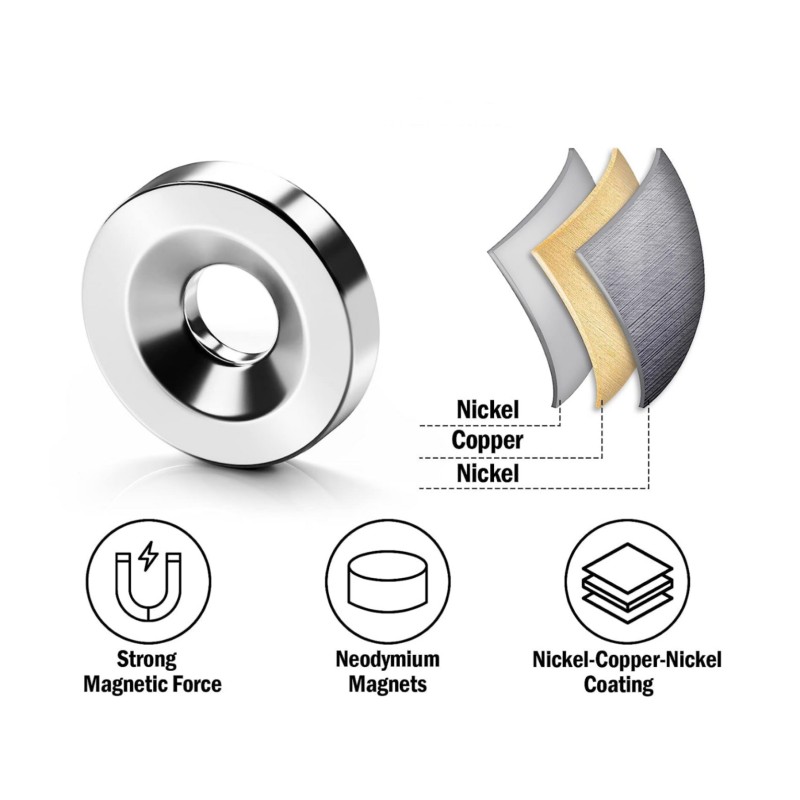

Most neodymium magnets are plated or coated separately, because neodymium magnets in their original form are very brittle and easy to break, and neodymium magnets have a high iron content, which will quickly oxidize without a protective layer, so protecting them is very important.

For NdFeb magnets, the commonly used coatings are nickel plated, galvanized, epoxy plated, gold plated, silver plated, plastic rubber coated, etc., why the epoxy coated neodymium magnets are a better choice, there are the following reasons:

First, compared with galvanized and nickel-coated Ndfeb magnets, epoxy coated provides better mechanical protection. The epoxy-coated forms a protective layer that can withstand shock, wear and rough handling, reducing the risk of magnet damage. Nickel plated, while providing a degree of protection, is not as effective in dealing with mechanical stress, and zinc coated acts as a sacrificial coated that corrodes away in place of the underlying material.

Second, neodymium magnets are highly conductive, which can be a problem in applications where electrical insulation is required. However, epoxy coated is an excellent electrical insulator that prevents current from flowing through the magnet, minimizing the risk of short-circuiting or interfering with electronic components. Therefore neodymium epoxy coated magnets are usually the better choice for electrical insulation applications.Gold and silver coateds are good electrical conductors and are often used as decorations, but the cost is relatively more expensive.

Third, the epoxy coated can be applied to the material by simple coating methods such as coating, spraying or dipping, which is easy to handle and assemble. For custom bulk neodymium magnets, the effect of epoxy coated on size is less than that of rubber coated, and the corrosion resistance of epoxy coated is stronger than that of rubber coated neodymium magnets.

In summary, the choice of these electroplated or coated depends on the specific application, environmental conditions and performance requirements, the most suitable is the best.

Hi! Click one of our members below to chat on