Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

These powerful industrial cup magnets are ideal for securing frequently used tools for easy access, and their durable epoxy coating allows them to withstand harsh working environments.

Color :

BlackSize :

D32mmOrder(MOQ) :

100pcsSample :

AvailableLead Time :

10-15daysPayment :

Paypal/TT/Credit CardWaterproof Epoxy Coating 100LBS Super Strong Cup Magnets

Product Description

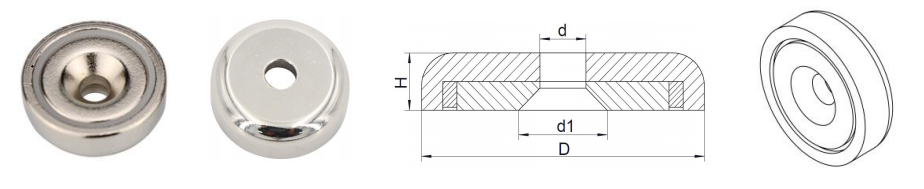

Size: 32x7mm M5.5

Shape: Cup

Plating/Coating: Black Epoxy Resin

Assembly: Stainless Steel Cup, NdFeB Magnet

Warnings:

Keep away from pacemakers and children

If damaged please dispose of completely

Product Features

Strong Magnetic Attraction

This permanent neodymium mounting pot magnet uses high quality NdFeB magnets and a cup shaped steel shell, providing concentrated and reliable magnetic force for a firm attachment to metal surfaces.

Durable and Long Lasting

The black epoxy coating on the surface is corrosion resistant and moisture proof, ensuring long lasting durability in both indoor and outdoor environments.

Easy Installation

The central threaded hole of the epoxy coated round pot magnet allows for quick and secure installation with standard screws, preventing slippage and facilitating easy position adjustment.

This versatile magnetic pot magnet is designed for a wide range of industrial and commercial applications:

Equipment and Machinery Mounting: Securely fastens tools, equipment, or components in factories, workshops, and production lines.

Metal Shelving and Fixtures: Attach signage, panels, or lightweight structures to metal surfaces without drilling.

Display and Exhibition Support: Ideal for exhibition stands, trade show displays, and retail locations requiring reliable temporary positioning.

Universal Metal Fasteners: Can be used for magnetic clamps, tooling fixtures, or any project requiring strong, detachable magnetic connections.

Model List

| Model | D (mm) |

d (mm) |

d1 (mm) |

H (mm) |

Weight (g) |

| SNA12 | 12 | 3.5 | 6.5 | 4.5 | 4 |

| SNA16 | 16 | 3.5 | 6.5 | 5 | 7 |

| SNA20 | 20 | 4.5 | 8.6 | 7 | 14 |

| SNA25 | 25 | 5.5 | 10.6 | 8 | 25 |

| SNA32 | 32 | 5.5 | 10.6 | 8 | 42 |

| SNA36 | 36 | 6.5 | 11.3 | 8 | 54 |

| SNA42 | 42 | 6.5 | 11.3 | 8.6 | 78 |

| LNA48 | 48 | 8.5 | 15.5 | 11 | 138 |

| LNA55 | 55 | 8.5 | 14.5 | 12 | 205 |

| LNA60 | 60 | 8.5 | 14.5 | 15 | 305 |

| LNA70 | 70 | 10.5 | 16.5 | 17 | 485 |

| LNA75 | 75 | 10.5 | 16.5 | 18 | 560 |

| LNA80 | 80 | 10.5 | 16.5 | 18 | 668 |

| LNA90 | 90 | 10.5 | 16.5 | 18 | 850 |

| LNA120 | 120 | 12.5 | 22.5 | 18 | 1520 |

Combination Usage Techniques

Way 1. Secure with Screws for a Sturdy and Reliable Fixation

Use the center threaded hole to firmly attach the magnet to metal, wood, or other surfaces using standard screws. This method ensures precise positioning, maximum attraction, and long term stability.

Way 2. Quick Installation with Double Sided Adhesive

If drilling is not possible, also can apply strong double sided adhesive to the bottom of the magnet. This allows for quick installation and easy removal while providing sufficient magnetic force for lightweight objects or temporary installations.

Way 3. Enhanced Flexibility with Combined Use with Other Magnets

It can be used in combination with other magnets or magnetic tools to enhance magnetic force or create custom magnetic components. This method is suitable for heavy duty adsorption, modular installation, or applications requiring adjustable positioning.

Packing&Shipping

Hi! Click one of our members below to chat on