Hefei Super Electronics Co., Ltd.

Hefei Super Electronics Co., Ltd.

What Are You Looking For?

As the world’s leading producer of neodymium magnets, China continues to push the boundaries of what’s possible in permanent magnet technology. From reducing rare earth consumption to enhancing performance and durability, Chinese manufacturers are making remarkable strides that are shaping the future of global supply chains.

🌿 Eco-Friendly Materials and Resource Optimization

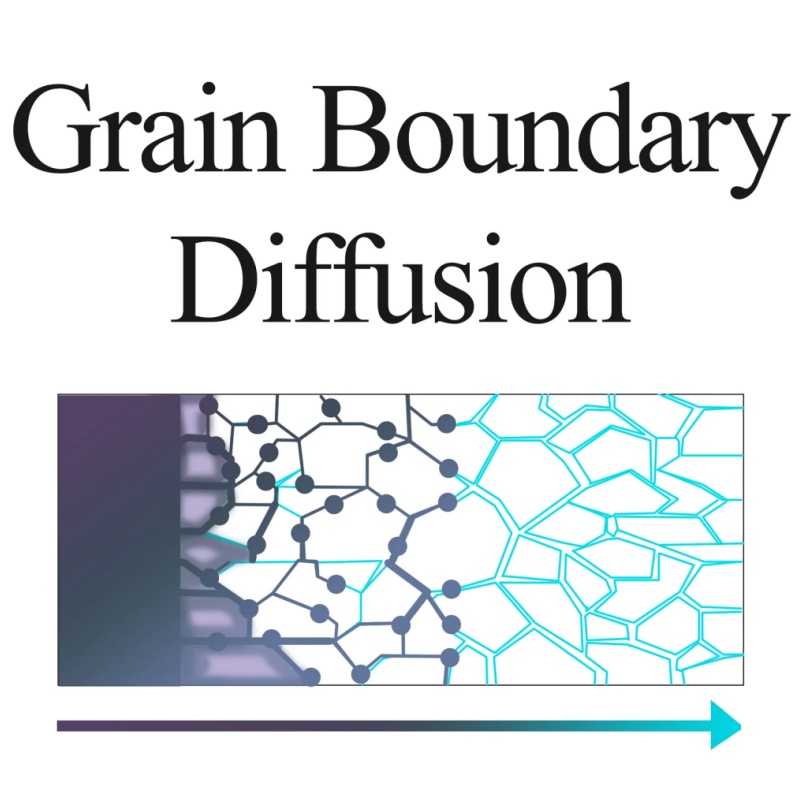

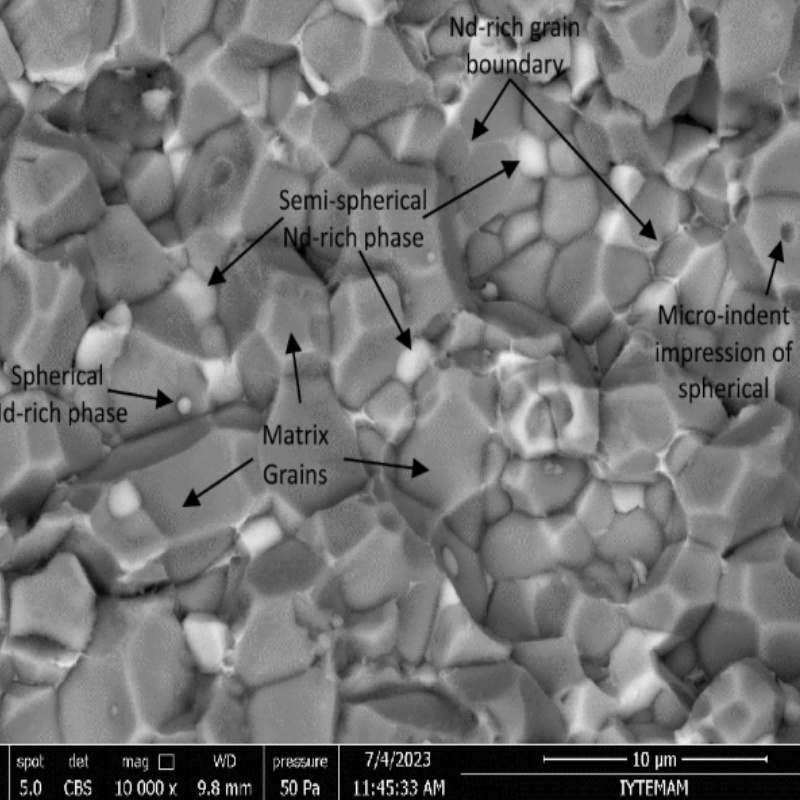

One of the key areas of innovation is the reduction in the use of heavy rare earth elements such as dysprosium (Dy) and terbium (Tb), which are costly and environmentally challenging to extract. Chinese researchers have adopted advanced grain boundary diffusion (GBD) techniques to maintain high coercivity with minimal rare earth usage. By localizing the diffusion of rare earth elements to specific regions within the magnet’s structure, manufacturers can produce high performance ndfeb magnets with significantly less environmental impact and lower production costs.

⚙️ High-Performance and Thermal Stability

To meet the rising demands of electric vehicles, wind turbines, and aerospace systems, Chinese factories are increasingly adopting nanocrystal microstructure control. This advanced technique refines the grain size of neodymium iron boron (NdFeB) materials, enhancing magnetic domain alignment and significantly improving energy output.

The result is magnets with higher magnetic energy density and superior thermal stability—ideal for applications that demand long-lasting performance under high temperatures, strong vibrations, or extreme working conditions.

⚙️ Advanced Coatings for Harsh Environments

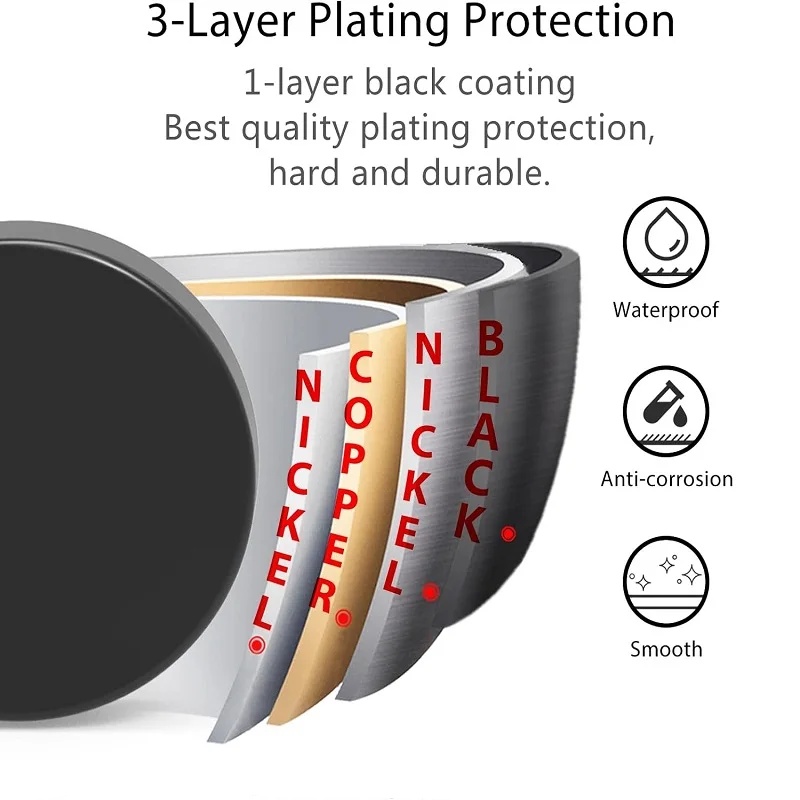

Durability is a key factor in magnet performance, especially in electronics, marine, and industrial environments where magnets are exposed to humidity, chemicals, or vibration. In such conditions, standard coatings often fail to provide sufficient protection, leading to corrosion and performance degradation over time.

To meet these challenges, Chinese neodymium manufacturers have developed hybrid protective coatings—typically multi-layer nickel-epoxy combinations—that offer excellent corrosion resistance and wear protection. These advanced coatings significantly extend the service life of neodymium magnets, making them ideal for high-humidity, chemically aggressive, or mechanically demanding applications.

🔧 The Road Ahead

With ongoing investments in automation, material science, and smart manufacturing, Chinese neodymium magnet industry is moving toward more customizable, efficient, and sustainable solutions. These innovations not only meet domestic needs but also provide high-quality options for global buyers seeking advanced magnetic materials.

Hi! Click one of our members below to chat on